Flash Microcontroller Programmer

【Reliability】

Result of Accumulated On-Site Support for Product Processes

Our NETIMPRESS has been manufactured and marketed for more than 20 years as an on-board flash programmer for development/production since the start of the use of flash memories in the on-chip ROMs of microcontrollers(MCUs).

For many years, we have worked to ensure the stable operation of the system as a product for development and production equipment, and many of our customers have adopted it.

【Follow-UP of Speedup】

Demand for High-Speed Programming from Large Capacity

Process evolution of semiconductors has resulted in higher processing performance and larger capacity of internal memory.The programming performance requirements for memories with larger capacity have evolved communication functions in order to transfer data in a shorter time.

NETIMPRESS offers faster target microcontroller communication performance, and also supports Gb-Ethernet host-connected interfaces, which will help reduce programming times in the future.

【Production Line Affinity】

Emphasis on Efficient Equipment, Diversity and Versatility

We have provided our NETIMPRESS products to many Production factory.

Due to the following merits, we have received high satisfaction and praise from customers even after the introduction of the product, and we continue to use it regularly.

- Continuation of equipment, advantageous versatility

- Reduction of production setup change time

- Variety of extended functions for production control

Hardware has been commonized and unique information such as different microcomputer vendors and microcontroller product types has been defined and separated into dedicated software.

In order to use the equipment after introduction for a long time, we have implemented a general-purpose design.

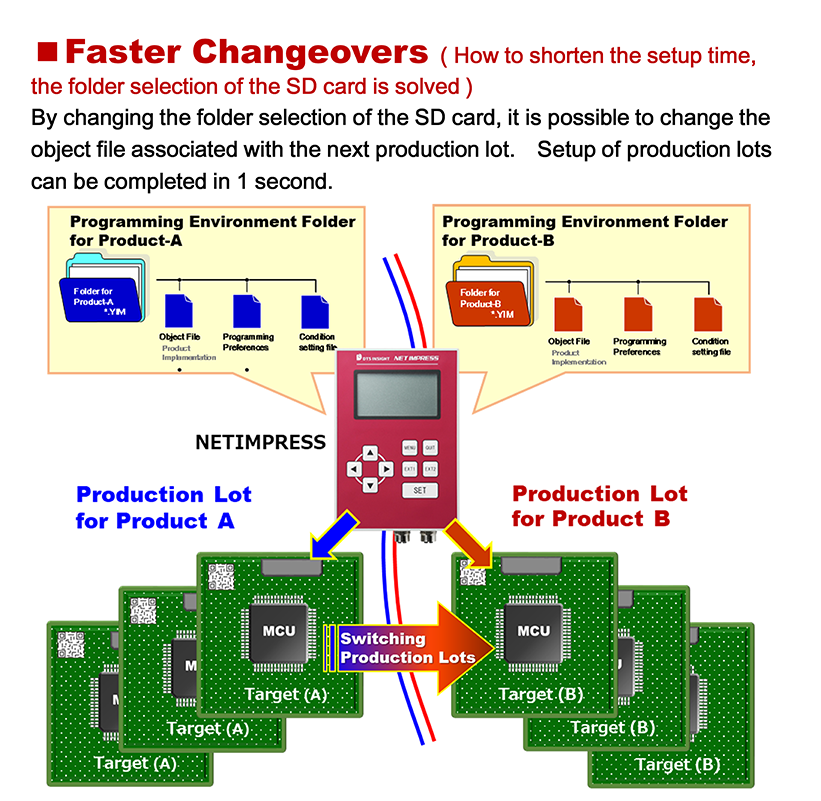

By utilizing the file management medium (SD Card) mounted in the programmer, it is not necessary to download the information of the program environment to be set each time the production lot is switched.

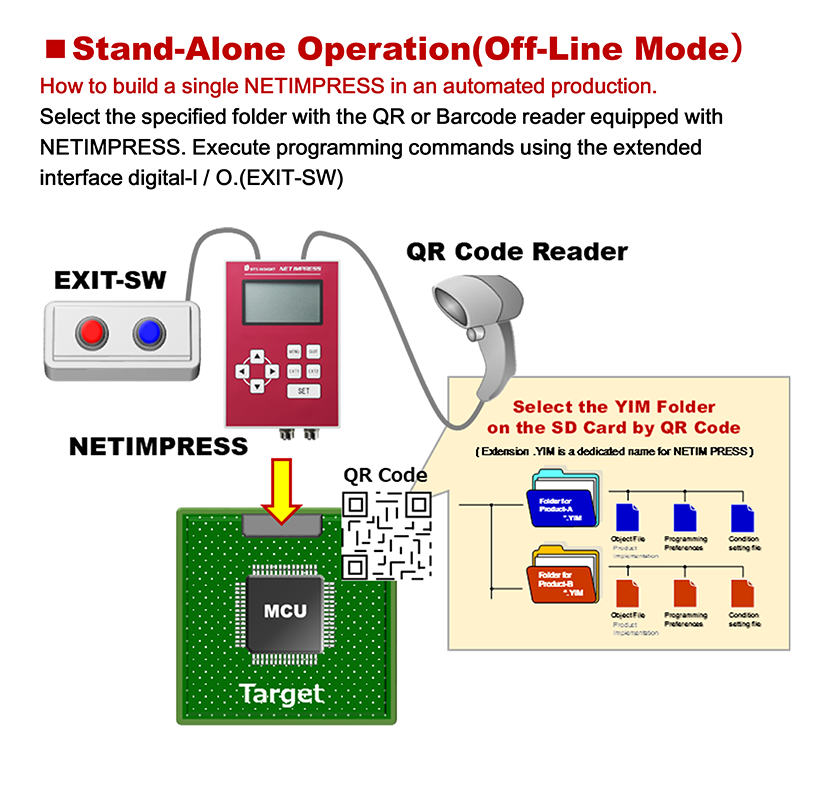

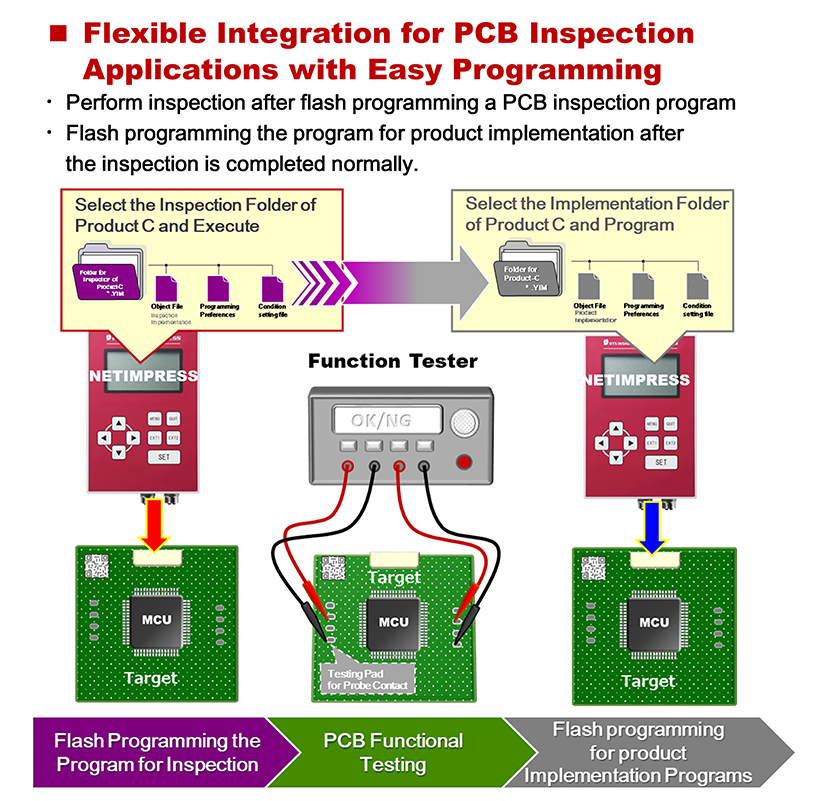

It is possible to select a programming type that recognizes manufacturing information (QR/barcode) on production control applied to assembly boards (PCB). Easy coordination of functional test fixtures by means of the input/output signal control mechanism extended to the main unit.(Digital IO control)

【Support for Security Measure】

Data Integrity at Manufacturing Sites

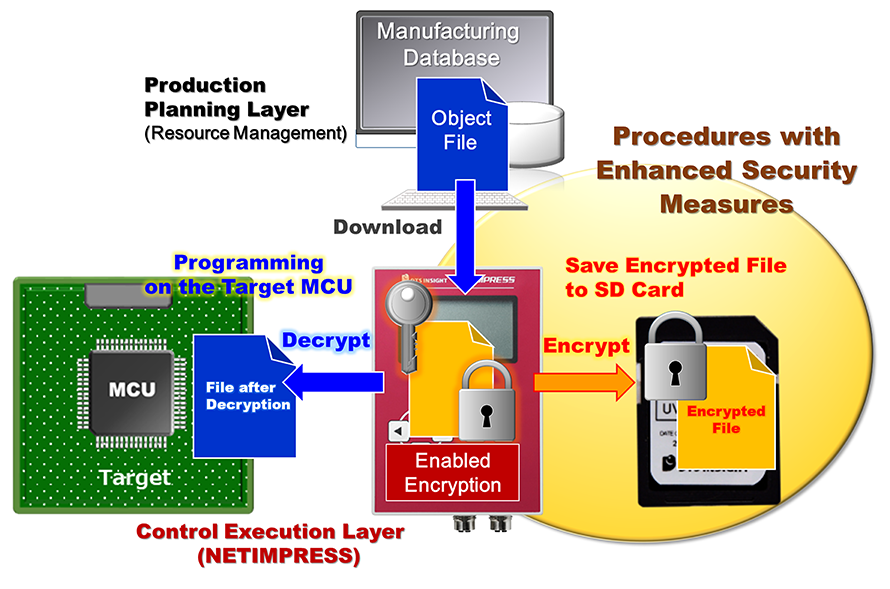

Tampering and leakage of data are believed to be a threat of external attacks even during product manufacturing.

After transferring the object data to be programmed into the target flash memory to our product, the data is encrypted.

Object data encrypted as a security measure is decrypted when programming to the target flash memory.

The storage medium SD card associated with our products stores object data of products, but encrypted data is stored to prevent information leakage.Even in the unlikely event of theft, the risk of information leakage is minimized.

In addition, security functions have been enhanced inside the microcontroller, and programming of individual encryption keys is also supported immediately before shipment.

How to Program the On Chip Flash Microcontroller(MCU)

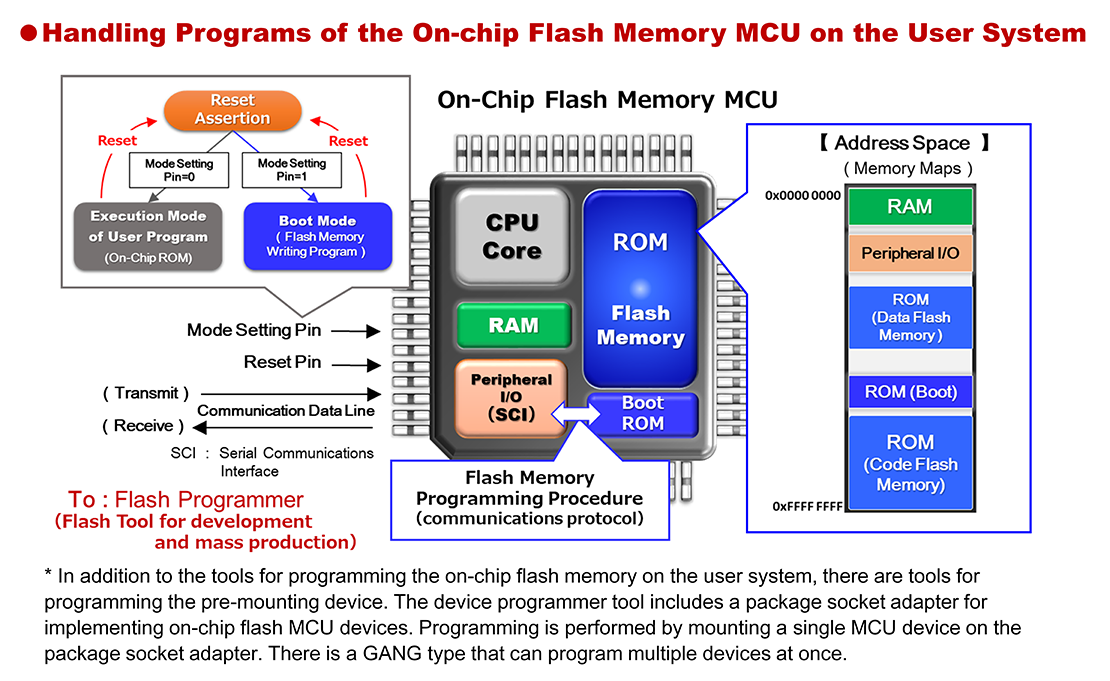

Flash memory is applied to ROM (Read Only Memory: non-volatile memory) mounted on most modern microcontrollers (MCUs).Flash ROM mounted on a microcontroller (MCU) is called "On-Chip Flash MCU" or "Flash MCU".

The following describes Flash ROM programming process used by many On-Chip Flash MCU.

In the on-chip flash MCU, the operation of "user operation mode" and "on-chip flash memory programming mode (Erase/Write operation program)" is selected according on the state of the mode pin when the reset pin of the MCU is released.

When the flash memory programming mode is selected,the dedicated internal Boot-ROM (on-chip flash memory writing program) of the MCU operates and the dedicated protocol for Flash ROM programming by the MCU peripheral IO communication interface (SCSI, etc.) is enabled.

Programmer connection and control method

The flash programmer (ROM writer) controls the reset pins and mode pins of the MCU mounted on the target and enables the flash memory programming mode.

When "Flash memory programming mode" is selected, the communication between the Flash Programmer and the On-Chip Flash MCU through the internal peripheral communication interface is communicated by the MCU-specific programming protocol.

Then, the programming control (erase/write) by the flash programmer is executed.

Even in user mode, part of Flash ROM area (data area, etc.) using the specified communication interface (CAN) can be partially reprogram.

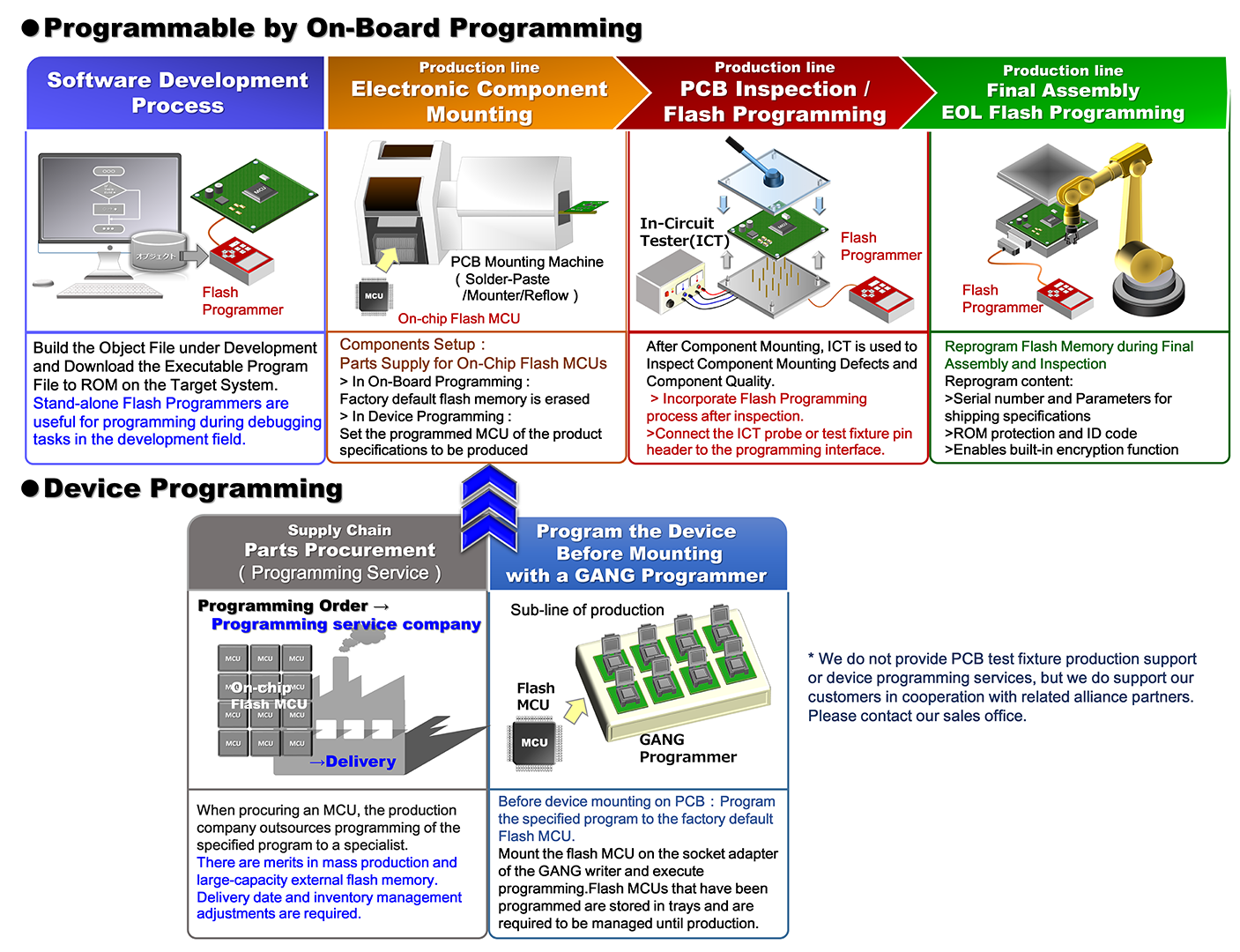

Situations for Using Flash ROM Programming

"Flash memory on-board programming method" is an effective means for analysis of the current situation of development and production line sites, and for solutions that focus on the actual situation. The "on-board programming method" can remove the burden on the development and production sites. For example, during product development, parameter tuning can be executed immediately on a real-time target, and even during production, when a software defect occurs urgently, debugging and verification can be continued until just before shipment.

In ECU products for vehicles, the content to be programmed into Flash ROM differs according to the software requirements (SRS:Software requirements specification) for each model, grade, and destination of vehicle system products.ECU product manufacturing requires on-chip flash MCU programmed according to SRS.

Flexible use can be expected with the "on-board programming method," which programs an on-chip flash MCU mounted on an assembly board.Even if the SRS of the ECU production lot is changed, the product response can be postponed until immediately before shipment.This method eliminates the need to manage unnecessary inventory, contributing to improved production efficiency.

To take advantage of these benefits, it is essential to adopt the "on-board programming method" in which programming is performed while the flash-on MCU is mounted on the assembly board.

Advantages of the onboard programming method

In the production line, there are problems such as shortening of lead time of parts supply, cost reduction of manufacturing cost, reduction of surplus inventory, and efficiency improvement of derivative product manufacturing.

The advantages of the "on-board programming method" as an effective means for production lines are explained below.

- Shortening lead times and reducing costs

- Reduction of surplus inventory and improvement of efficiency of derivative product manufacturing

- Easy to adjust the period of design, development, evaluation, and quality inspection

In-house production can reduce the cost of flash programming service. (cost of outsourcing)

Reduces time and management costs associated with rework when placing orders with subcontractors.

Enables production of "Just On Time" by onboard programming on the production line

without having unnecessary parts inventory.

Flexibility to respond to sudden changes in production plans due to specification changes and defect countermeasures.

Even if the delay in the development process of the software to be implemented in the MCU affects the release time,

flexible process adjustments are possible with the timely programmable production line.

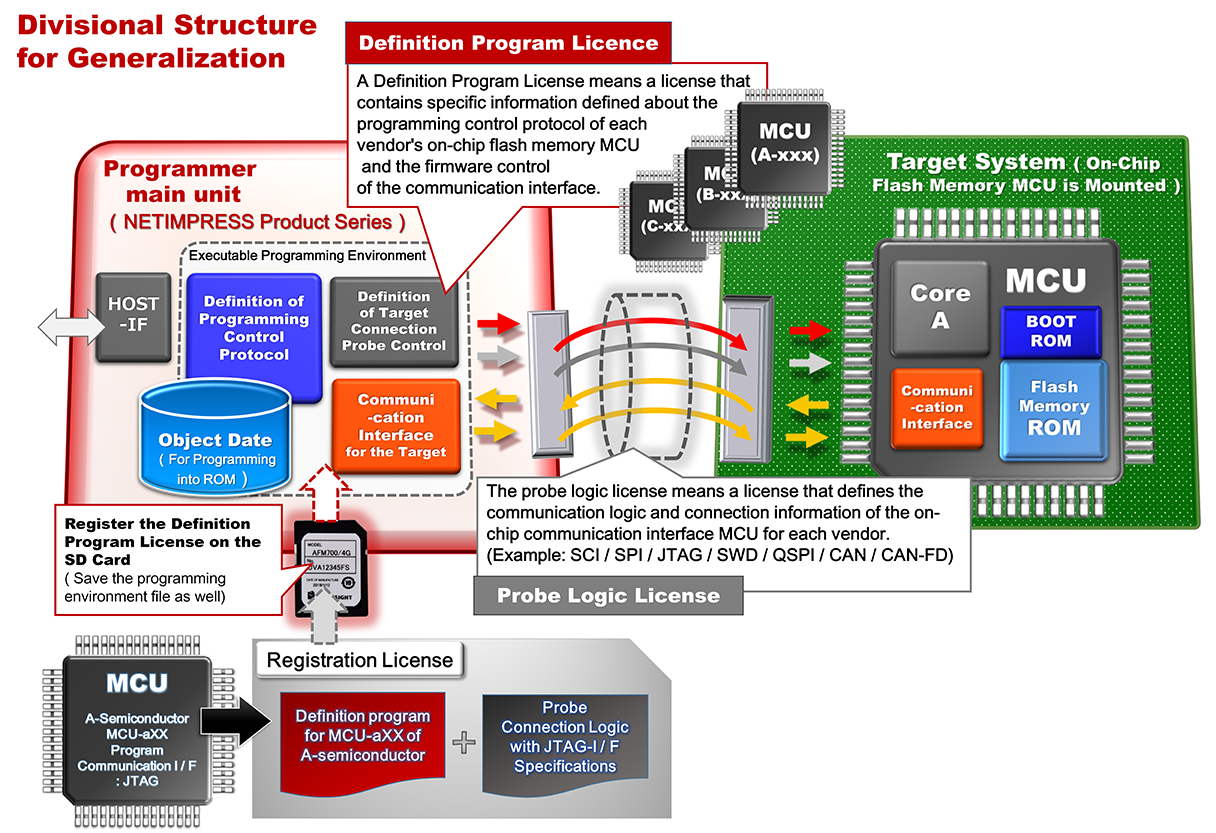

Generic Design that Shares Hardware, Software Defines Device-specific Information, and is Flash Device Independent(Facility Assets Friendly to Development and Production Sites)

NETIMPRESS series is a general-purpose flash programmer that separates the common part from the unique part.The unique part has been converted into software and made into a license file that can be purchased additionally.

The Unique Part license is a software license that defines the unique information related to on-chip flash memory MCU programming and the logic information of the target-dependent communication interface.By adding a unique division license according to the product development and production of the customer,

it is possible to accommodate newly adopted microcomputer programming.

What is a generic programmer's unique license?

- Definition Program License:

- Probe Logic License:

Flash programming protocol specification for each device

(MCU specific firmware for communication)

Logic firmware for communication specification and

wiring connection corresponding to physical interface

Based on general-purpose hardware, it is possible to extend different devices mounted on each product by adding unique licenses.Because hardware equipment assets are common, operation costs corresponding to small-lot, large-variety products are reduced.

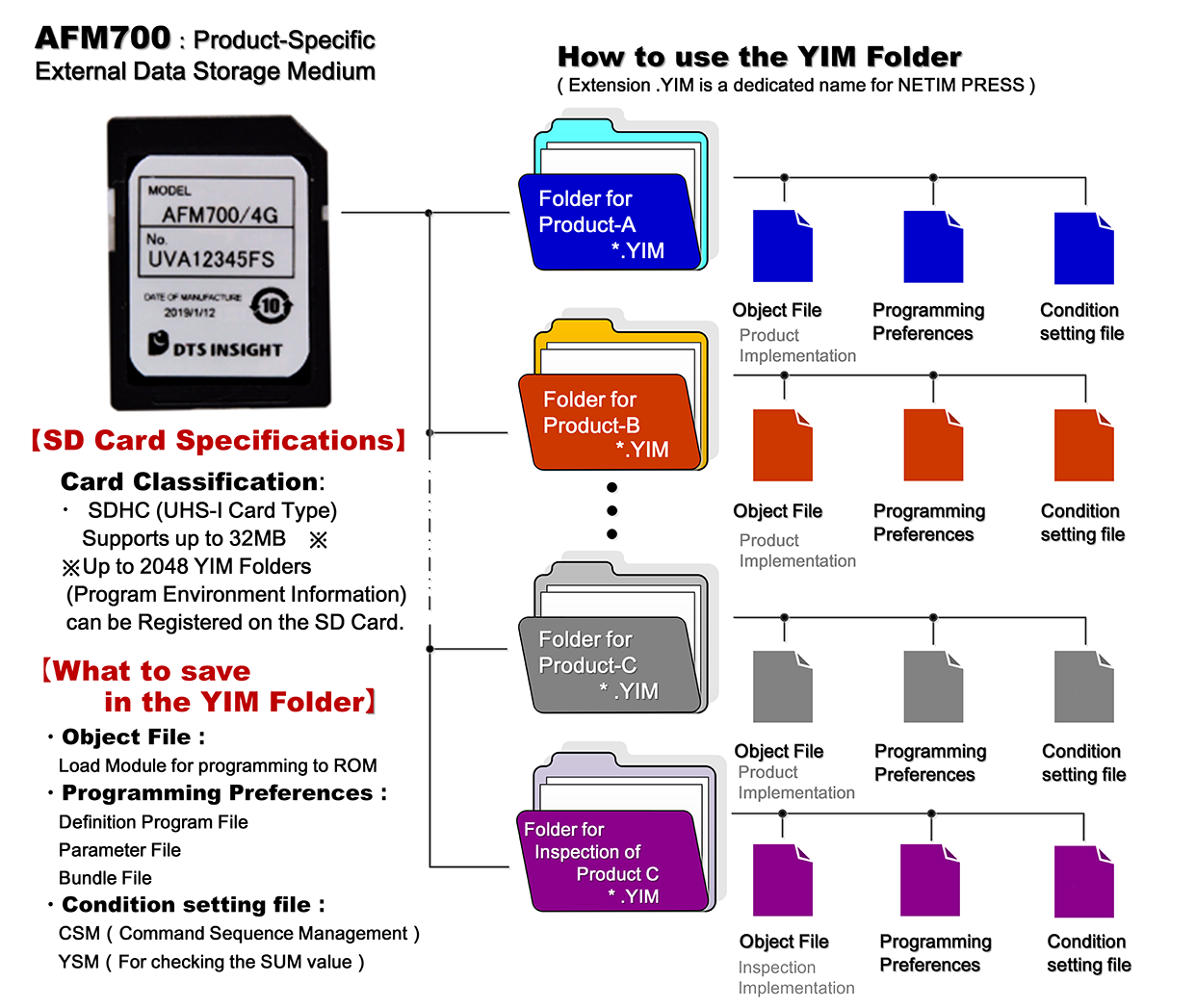

Improve Production Line Productivity by Utilizing a Dedicated Storage Medium (SD card)

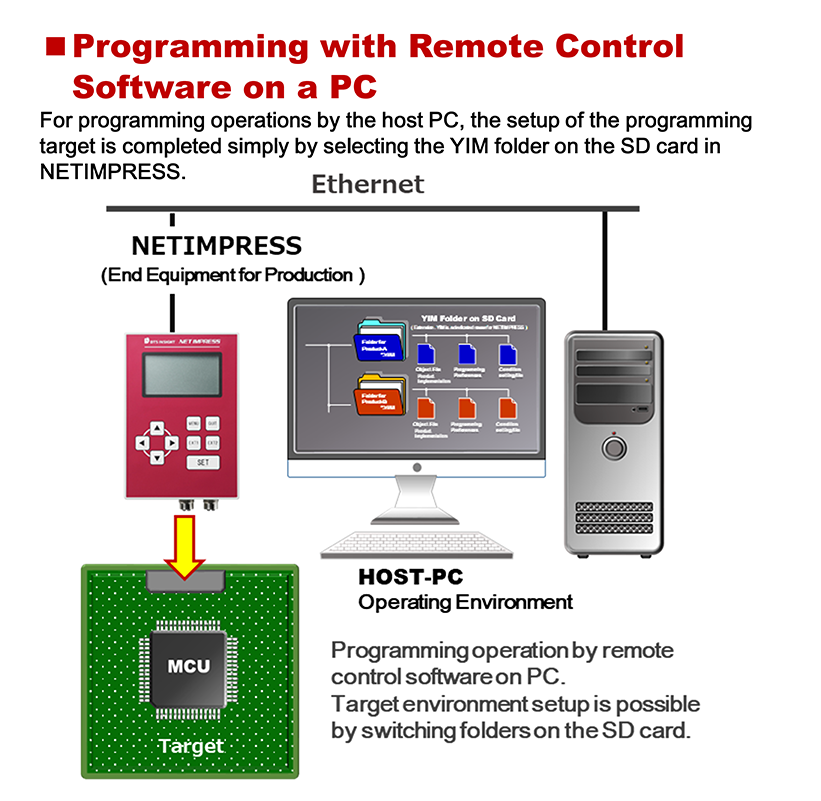

NETIMPRESS series saves the programming environment on a dedicated SD card by enabling high-speed programming online and standalone.The programming environment for each programming target is saved in the dedicated folder (extension: YIM) of the SD card.

Programming to the flash memory of the on-chip flash MCU at the production line or development site can be completed simply by specifying a folder and starting programming.Since the product information is stored in a dedicated storage medium (SD card), there is no need to download the product programming environment from the equipment setting information on the production management server to the programmer when starting the production lot.When switching production lots, the preparation for production lots is completed in just one second only by changing the folder instruction of the SD card.

The maximum memory capacity of the dedicated SD card is 32GB (*).

(* 2048 YIM folders can be saved)

Folder configuration of the dedicated storage medium (SD card)

Situations that utilize the dedicated SD card programming environment

Support for Security Measures

The risk of data theft or tampering by malicious third parties cannot be denied even for terminal devices.NETIMPRESS series has been enhanced to ensure that information is operated in a secure environment.

As a security measure for protecting object files, this feature automatically encrypts files.The object files saved on the internal SD card of NETIMPRESS are designed to prevent unauthorized access from outside.

Even if a third party takes out the SD card alone, the internal files of the SD card are encrypted.When the SD card is mounted on the NETIMPRESS main unit and programming is started on the target MCU, the object file is decrypted and programmed.

There is no need for complicated file management or security operation procedures.This secure environment is available in the encryption mode of NETIMPRESS Series (avant/acorde), which is less expensive for users.

Products Lineup

-

NETIMPRESS avant

A standard flash programmer that can be used from development to production lines

New product with enhanced versatility, high-speed performance, and expandability -

NETIMPRESS acorde

Multi-channel flash programmer for mass production lines

A new product that can arbitrarily mount up to 9 module-type programmer units on the base unit body -

Software for

remote control

Programmer remote control software

Programmer environment settings, definition program license registration, programming execution control