General-purpose programmer

NETIMPRESS avant

On-board programmers that can be used in various at sites such as development, production lines, and maintenance scenes.

General-purpose compact version compatible with a wide variety of On-Chip Flash Memory MCUs.

In recent years, the environment of manufacturing has reached an era in which "variability," "uncertainty," and "complexity" are intertwined, making it difficult to predict.At development and production sites, the spread of IT and the evolution of IoT and AI technologies are creating new products and value-added services.

The product value demanded by the market and consumers is diversifying, and manufacturing with diversity is required.We aim to be a product that responds to changes in the environment so that our customers can use our products with peace of mind for many years to come.

Product Overview

(Compact Product with Enhanced Safety and Speed, Inheriting General-Purpose and Reliability)

NETIMPRESS series is a flash-on-board programmer that is widely used in the field of development/production line/maintenance etc.

NETIMPRESS avant is a third-generation programmer product that has undergone five model changes to date, inheriting the concepts and functions of existing products, and further enhancing functions and performance.

Around the time when flash memory began to be adopted for the on-chip ROM of MCUs for automotive ECUs (electronic control units).The control software development site for ECU development requested a general-purpose flash programmer product that does not depend on each MCU.

In response to customer requests, we have released a general-purpose flash programmer product.As ECU development progresses, we received requests to adopt the tools verified in the development to the programming equipment of the production line, and have evolved as a programmer for the production site.

At development, production, and maintenance sites, there are procedures for partially modifying the flash of programmed ECU products according to the purpose and application (software revision, model, grade, destination).

Since the beginning of sales of the NETIMPRESS series, it has been compatible with the function of reprogramming a specific area of flash memory via CAN communication of the in-vehicle network.

NETIMPRESS avant also inherits it.

It is NETIMPRESS avant to improve the reliability and versatility that we have built up so far, and to enhance the speed, safety measures, functions, and operability with a compact (size of bible) design.

【Key Features】

- Stand-alone environment that meets development and manufacturing needs (Easy to operate and convenient to use)

- The larger capacity SD card enables programming of multiple objects even in offline environments

- Enhanced expandability even for handy type, accurate reliability and mproved affinity with manufacturing sites

- Barcode reader connection is possible (product type selection), DIO-IF signal expansion(to execution control from PLC, patrol, etc.)

Improved noise immunity based on experience accumulated as equipment at manufacturing sites

(Enhanced the shield ground inside the housing and improve the transmission line of the probe cable to differential) - Increased equipment utilization, programming of two flash memories on a single programmer

- Equipped with a 2-channel probe cable connection interface as standard, one unit is sufficient for two programming executions of the main/sub MCU

- Contributing to production efficiency through faster download speeds and shorten takt times

- The processing performance of the main unit has been improved to support Gigabit Ethernet for the communication interface between hosts and to follow the maximum baud rate of 40 Mbps for communication with the target.

Compared to conventional products(PC communication time reduced to 1/10 or less, programming time reduced by 30%) - Pursuit of generalization: Softwareization of unique communication structures (programming protocol specifications) and physical constraints (target connection wiring specifications)

- Hardware of the main unit and probe is Commonized. Software license for specifications related to specific programming that depends on microcontrollers.

- Supports a variety of target IFs:SPI/JTAG/QSPI(PHX400)・CAN/CAN FD(PHX410)

- Probe License: Converts target-specific communication interface wiring to logic firmware.

CAN/CAN FD reprogramming support is available in the original protocol (UCOP)

We also accept the development of custom definitions that correspond to the protocol the customer is using - Enhanced Security:ncrypting Stored Files to Prevent Information Leaks

- Object files are encrypted when saved in the main unit of the programmer. Decrypt it just before programming into target flash memory.

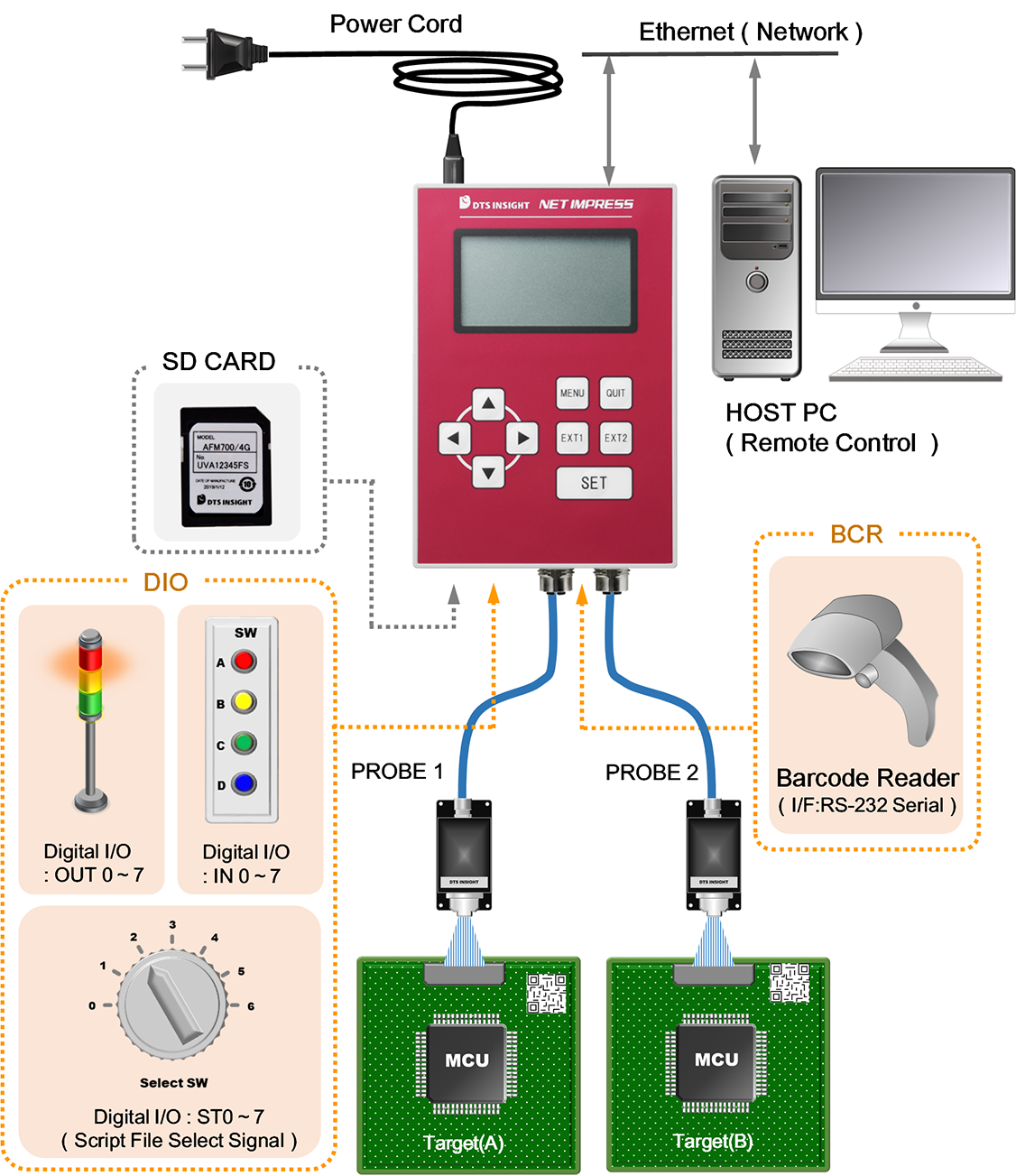

Expanded System with Enhanced Compatibility with Manufacturing Site Equipment "Collaboration Leading to Production Equipment"

"Collaboration leading to production equipment" in NETIMPRESS series

To maintain a high operating rate as a flash programming facility for mass production of electronic component boards on production lines, we have strengthened the function of linking with peripheral production equipment.

In order to improve the operating rate, it is important to have "Collaboration leading to production equipment" that is compatible with existing production equipment.In order for the programming tasks of existing products to penetrate further into the users' on-site equipment, we are enhancing the extended interface for the functions of the main unit.

The functions of the extended interfaces are inherited from the cooperation and coordination of production lines with equipment control and data utilization that have been accumulated through NETIMPRESS series-up to now.In NETIMPRESS avant , the number of signal wires for connection probes and Digital-I/O has been increased, and AC adapters that could lead to connection incidents have been eliminated, and power supply circuits have been built into the main unit.

Here is an image diagram of the connection development of "Collaboration leading to production equipment".

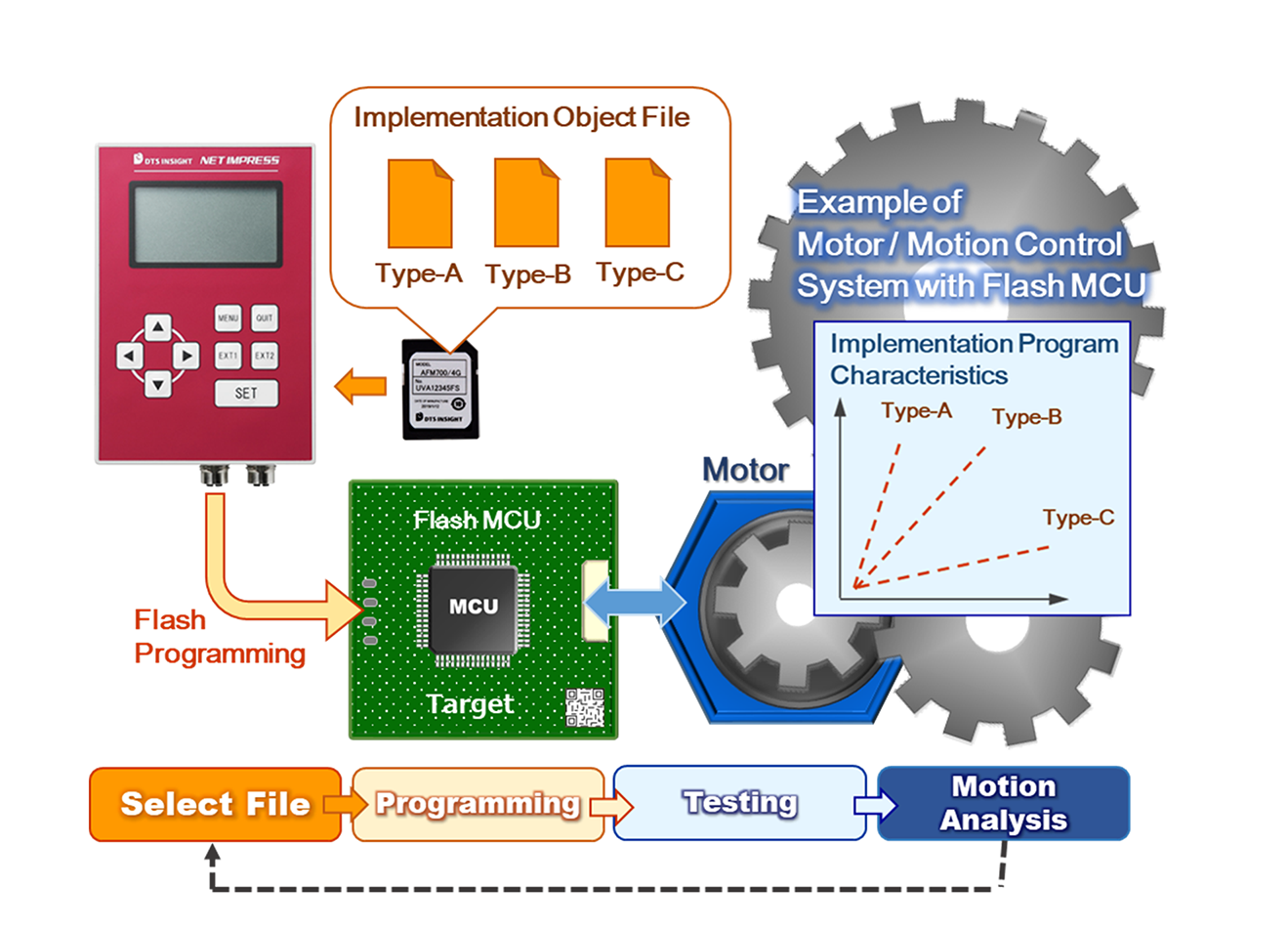

The Stand-alone Environment also Expands the Scope of Use at the Development and Manufacturing Sites

The requirement for programming flash memory at the development and manufacturing site is that it can be programmed multiple files multiple times under various conditions.In the production plant, a multi-functional PC is simply a device that selects files and downloads them to the programmer.If the purpose of the PC is to download object files to the flash programmer, NETIMPRESS avant alone can save multiple object files in the same way as a PC.

In "NETIMPRESS avant" stand-alone (offline) environments, select files according to the purpose of the site and use programming multiple times.

Below are some of the uses of development and manufacturing sites.

【Scenes for Use at Development Sites】

It is an effective tool for flash memory parameter tuning and multiple objects testing in the system test/testing site, which is the climax of development.

If several object files are saved in "NETIMPRESS avant"'s SD card beforehand, even in a stand-alone operating environment, it is possible to select files according to on-site test applications and flash-program multiple objects.At the development site, "NETIMPRESS avant" contributes to the iteration cycle of programming the software to be evaluated, testing execution, and measurement verification.

SD card with a maximum saved capacity up to 32MB can be used.

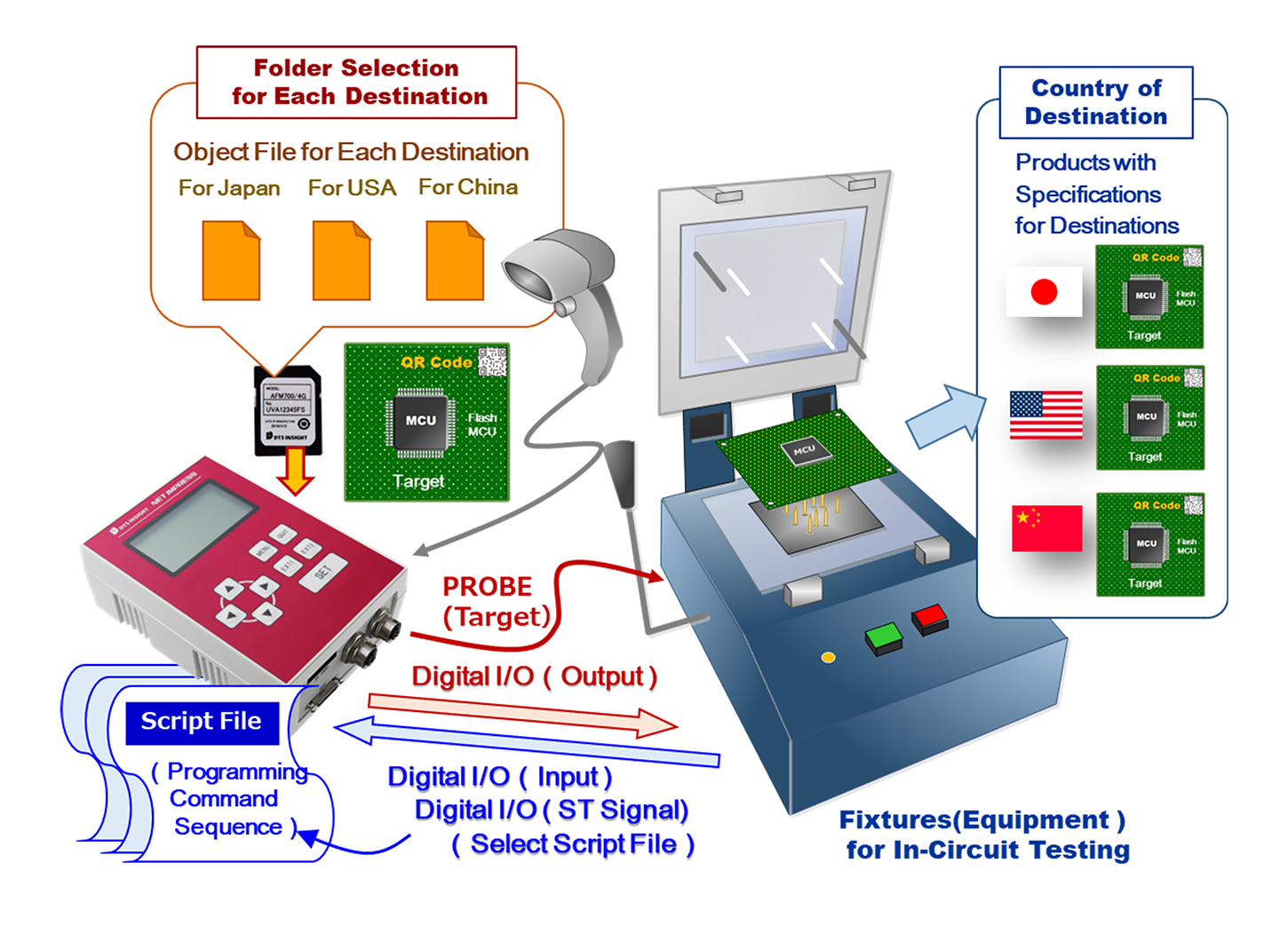

【Scenes for Use at Manufacturing Sites】

In the production line, an object file is specified for each product to be manufactured, and programming is executed.With NETIMPRESS avant, it is possible to work in a stand-alone (offline) environment as well as online without connecting to the PC that manages this production.

"NETIMPRESS avant" provides a mechanism to automate programming for each product that is produced even in a stand-alone environment.For programming automation, use the SD-card/QR-code reader /Digital IO of "NETIMPRESS avant"'s extended function.

Associate the file folder saved in the SD card with the QR code in advance.Scan the QR code containing the product attributes with a QR reader, and specify the object file of each product saved on the SD card from the read data.Automation also can be performed by saving the programmer's operation sequence to a script file.

The operation sequence defined in the script file can automate a series of programmer operations such as activating programming based on the input value of the Digital I/O signal and outputting the execution result to the Digital I/O signal.

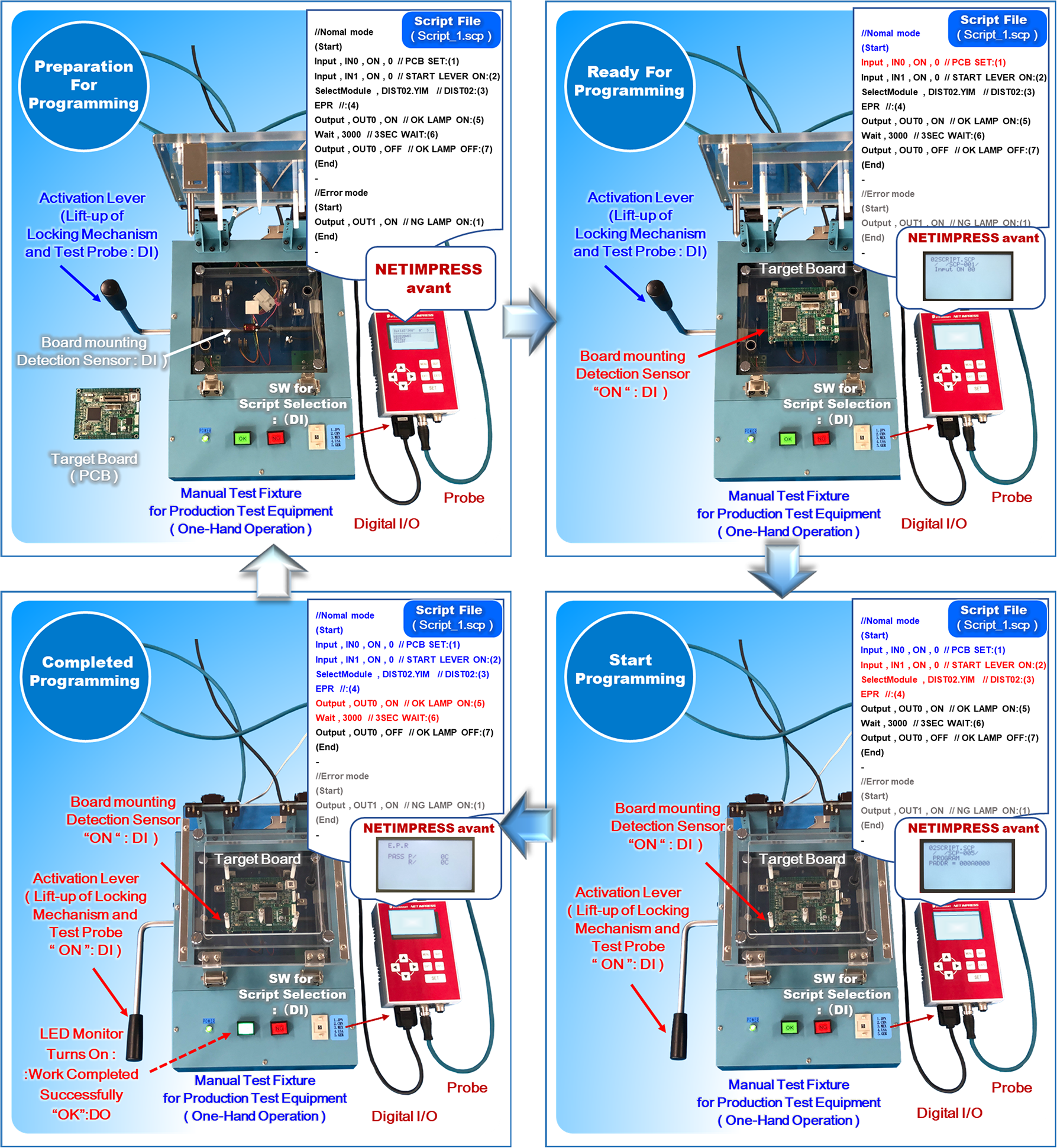

Automating Programming Tasks in a Standalone Environment(Example Script Execution Behavior)

NETIMPRESS avant can use folder selection and Digital I/O to automate programming operations even in stand-alone environments.NETIMPRESS allows programming action sequences to be defined in script text and saved as script files.

Script files can be used for "script selection" by barcode/QR code readers, and "script execution" based on the results of defining conditions for Digital I/O (ST) input signals.

(See AZ488 on the support page for information on generating script files.)

Below is an example of executing a script file that links the board test fixture of the manufacturing equipment and the ”NETIMPRESS avant”.

【Programming Sequence by Executing Script File】

Preparation :Select a scripted file (specified by Digital IO ST pin (the select switch is connected))

Ready :The PCB board is detected on the board fixture(The PCB-mounted sensor is connected to Digital DI)

Start : Operation starts when the start lever is pushed down and locked(the start lever is connected to the Digital DI input)

Completed : Checking the ERP operation of the program sequence and output Normal/Error results( Outputting the result of ERP operation as a Digital DO)

To Improve Usability:Two Microcontrollers can be Programming with One Unit.

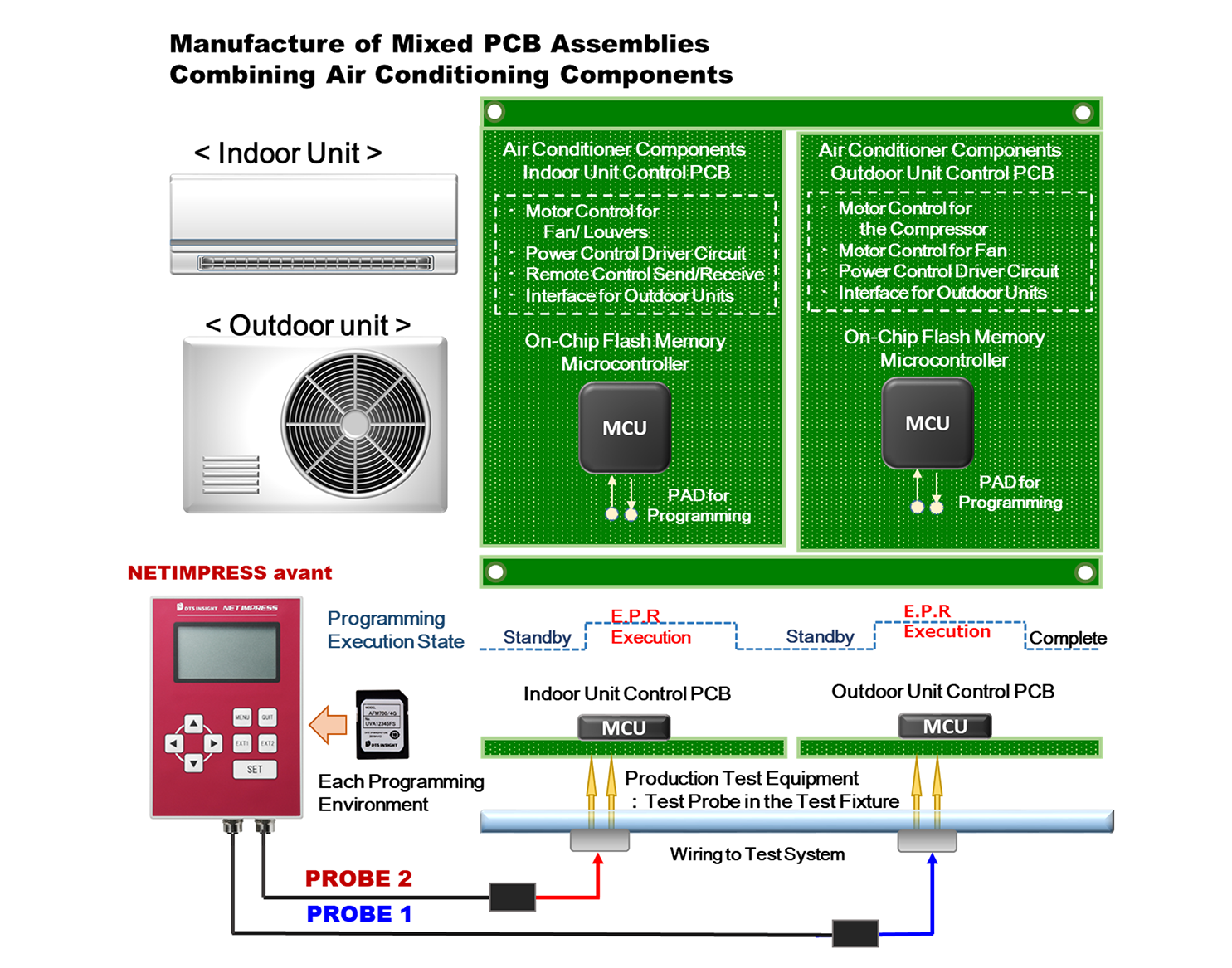

Many customers' production lines using NETIMPRESS are production lines in which multiple MCUs are mounted on mixed assemblies of several PCBs or multi-piece PCB assemblies.Multiple programmers are used to support programming of multiple MCUs.In order to improve the productivity as a single programmer device, the NETIMPRESS avant is equipped with a 2-channel probe connection interface as standard equipment so that even one of the main unit can support two MCUs.

In the past programmer products, the probe cable was a 1-channel connection.Therefore, two programmer products were required to programming two MCUs.At some sites, the wiring for switching the probe cables of the programmers corresponding to each MCU was switched using an external electromagnetic relay to prevent electrical collisions.The program environment of each target MCU must be configured and managed for each programmer.

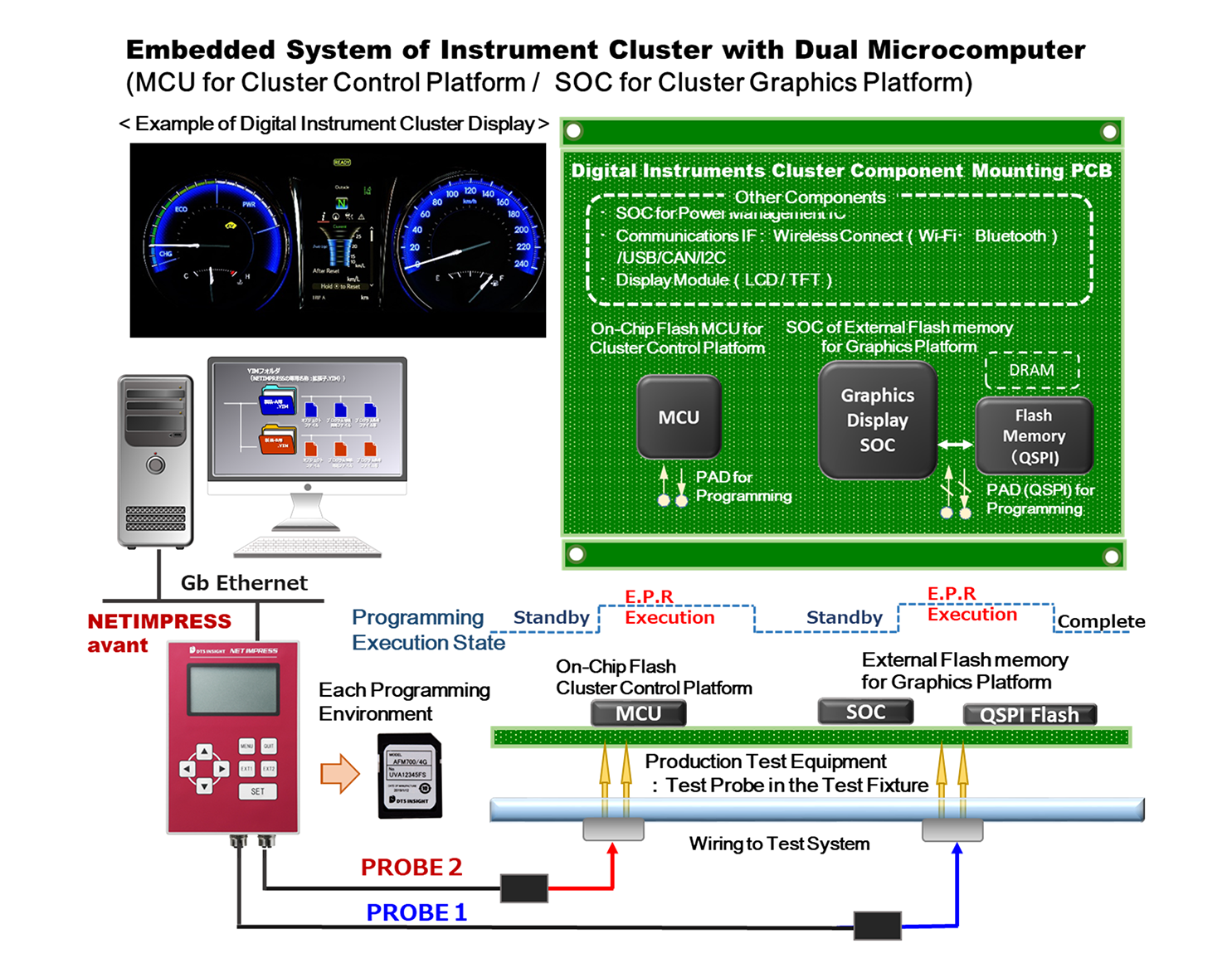

In NETIMPRESS avant, the task of switching programming environments and probes for each MCU is simply changing the internal settings of the main unit.In order to make effective use of this advantage, an example of a use case in which two MCU are mounted on a PCB is introduced below.

As an example of the production of highly diverse digital instrument cluster products, it is assumed that various types of programming will be performed on the control microcomputer and graphic control SOC mounted on a single PCB.

We recommend using PC Online for production lines with many product developments.

(For online use, refer to the Remote Control Software page)

Product Specifications of NETIMPRESS avant

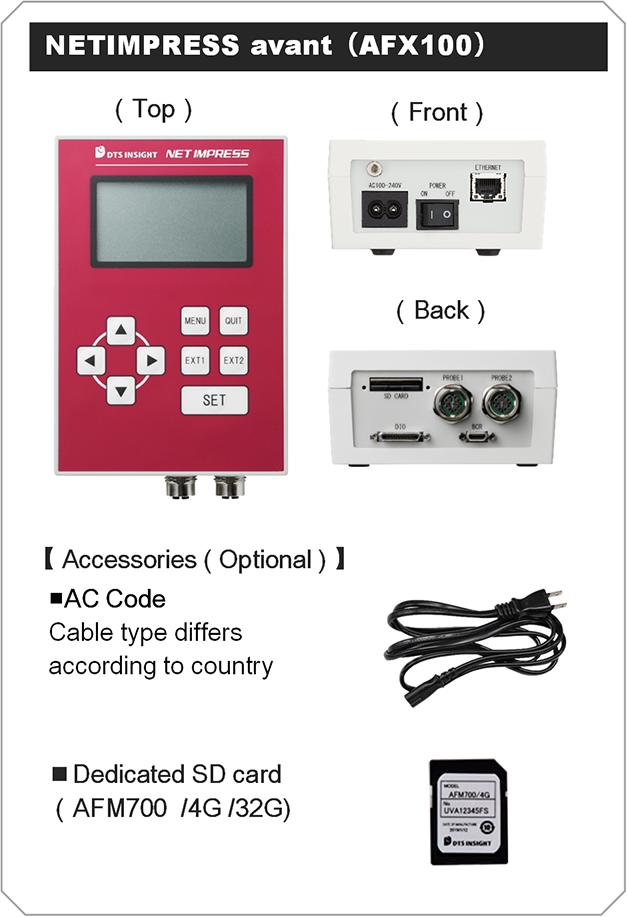

●NETIMPRESS avant(AFX100)

This is a general-purpose programmer for high-speed programming of on-chip flash MCU or flash memory connected to the external bus of a microcomputer.

【Display LED・Operation SW and connector】

<Top surface>

・LCD(Liquid crystal display:Displays various information,such as model name of definition

program and address etc)

・Key(Membrane switch:Operation keys for stand-alone)

<Front>

・AC Inlet (AC cable connector)

・LAN Connector (For Ethernet connection)

・Ground Terminal(For ground terminal)

・Power SW(Main unit power switch)

<Back face>

・SD Card Slot (Dedicated SD card slot)

・Target Connector 1/2(Probe connection x2)

・DIO Connector (For Digital I/O)

・BCR Connector (For barcode readers)

【Basic Specifications】

・HOST interface:Ethernet(10BASE-T/100BASE-TX/1000BASE-T)

Built-in 9-PORT HUB

・Storage environment -5 to 50℃ ・Operating temperature 5 to 40℃

・External dimensions 160(L)×110(W) ×55(H)mm

・Weight 750g

・Power Supply AC100-240V 50-60Hz

・Consumed power Less than 12W(0.25A)

【Accessories (Optional)】

・AC code(Cable type differs according to country)・Dedicated SD card(AFM700 /4G・/32G)

NETIMPRESS avant/acorde Common Accessory Product Specifications

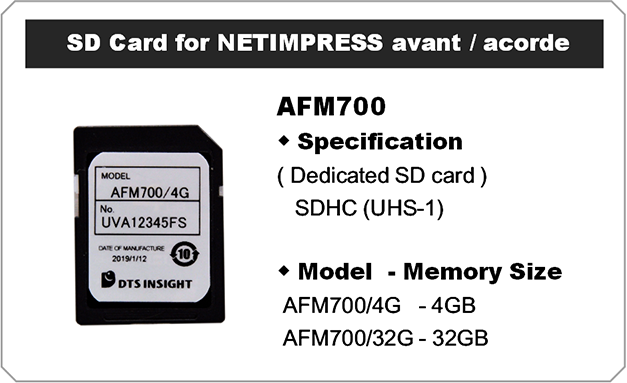

●Dedicated SD card(AFM700)

Dedicated SD card for AFX100 and AFX210 products.

It supports up to 32GB of memory size (UHS-1 standard) for high-speed data access.

Programming environment data is saved in the YIM folder in the same way as conventional products.When using programming, it is possible to instantly switch the YIM folder and change to the next target microcomputer.

●Definition Program & Probe Logic License

NETIMPRESS avant/acorde is a general-purpose flash programmer.We license each semiconductor vendor's flash programming protocol for program definitions (firmware for communication) and probe logic (logic firmware corresponding to physical interfaces).It is possible to expand compatible devices by adding a license to the SD card.

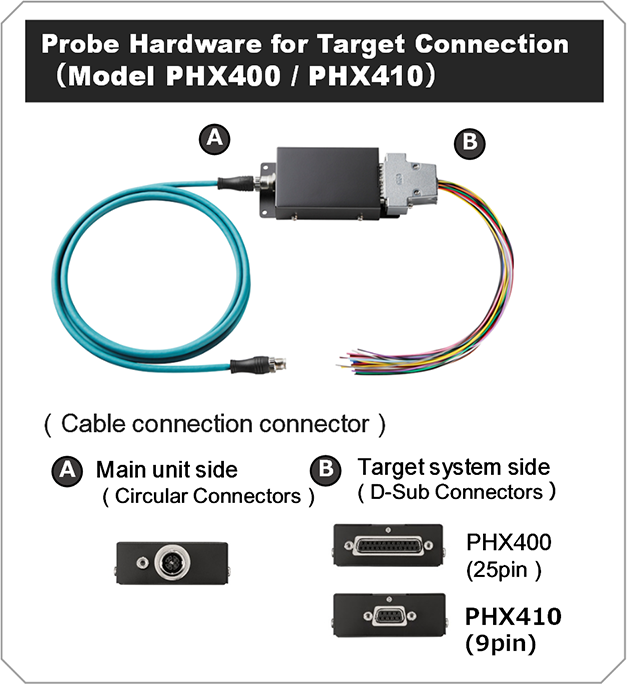

●Probe cable(PHX400/PHX410)

PHX400 is a multi-interface probe cable for various interfaces.

By default, serial communication and SPI are supported, and other interfaces can be expanded by adding a probe logic license.

PHX410 is a probe cable for CAN/CANFD. It can be used for reprogramming data for shipping destinations in the final process (EOL: End-of-Line) task in the ECU production line of automobiles.

【Basic Specifications】

・Cable length:

Programmer side 2m/Target Side 30cm

・Connector

Programmer side Round connector 8pin

Target Side D-SUB connector

(PHX400:25pin・PHX410:9pin)

・External dimensions 65(W)×95(D)×25(H)mm

【Probe Logic License】

Probe logic (firmware corresponding to physical interfaces) is provided under license.

It is possible to support the probe interface by installing the license on the purchased probe.

・PLX410 : Serial probe logic license(Standard installation on PHX400)

・PLX420 : JTAG probe logic license(Paid license) For PHX400

・PLX430 : SWD probe logic license (Paid license) For PHX400

・PLX440 : QSPI probe logic license (Paid license) For PHX400

・PLX460 : BDM probe logic license (Paid license) For PHX400

・PLX450 : CAN/CAN FD probe logic license (Standard installation on PHX410)

Supports CAN/CAN FD Reprogramming

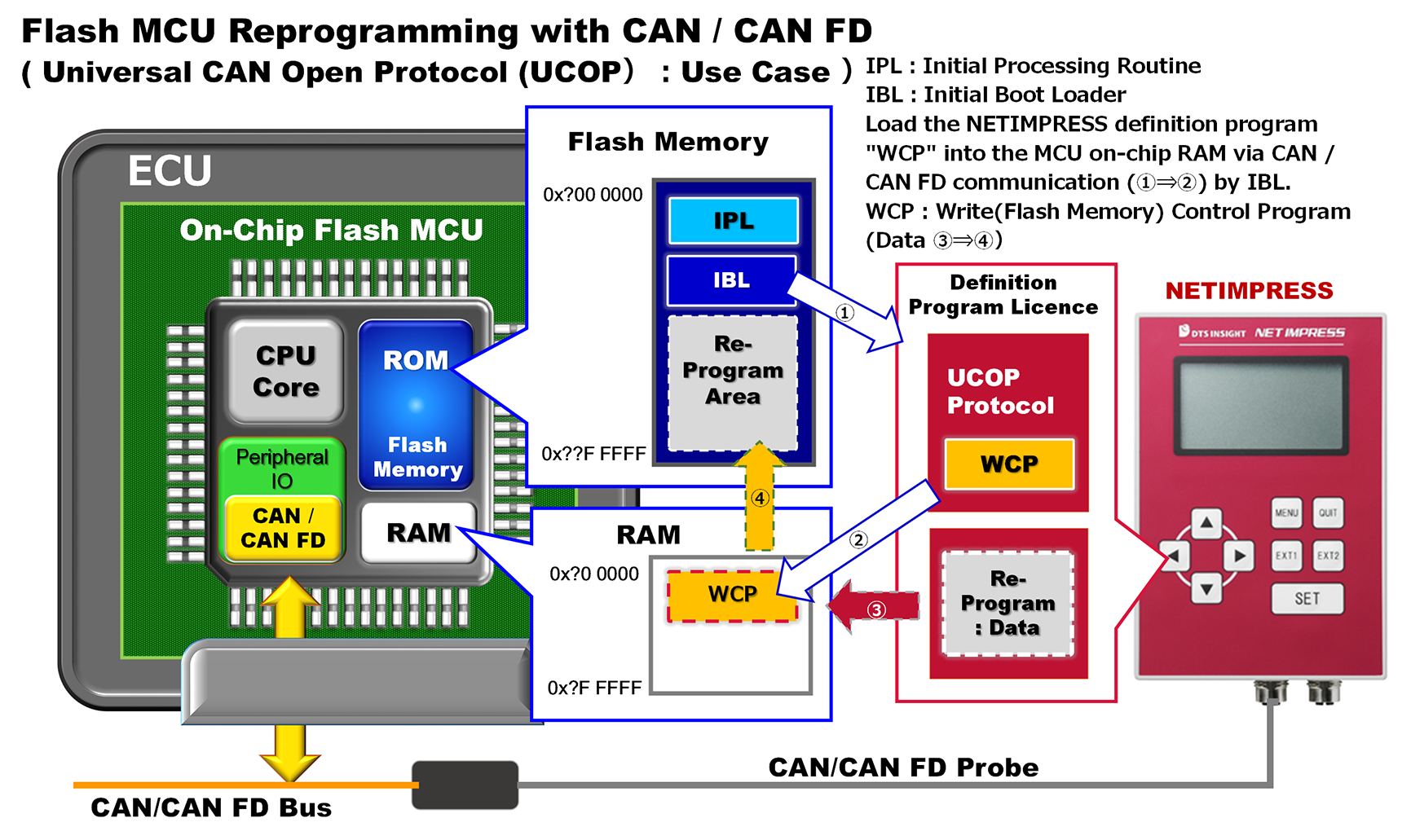

Reprogramming is flash programming to change specific code or data in the internal flash through the MCU's self-programming mode.Self-programming mode is an operation in which the MCU itself erases or rewrites a specific area of the internal flash memory by executing code that rewrites a specific area of the internal flash memory upon request from an external tool while the MCU application program is running.(The user operation mode (*)).Reprogramming is used in development, manufacturing, and maintenance for data tuning, data addition at the time of manufacturing shipment (EOL), and application software update.

Reprogramming tools for automotive ECU applications are standard programming tools that use CAN/CAN FD communication.Reprogramming requirements require the implementation of a bootloader that enables self-programming via CAN/CAN FD communication between programmer tools and MCU internal peripheral IOs.After CAN/CAN FD communication connection between the bootloader on the MCU and the tool, the programming operation of the on-chip flash memory is realized through the programming control protocol implemented in the MCU.

In order to make use of our programming environment by customers, we are engaged in many custom developments such as various CAN/CAN FD protocol support and boot loader and related programming controls for MCUs.We can also provide our own CAN/CAN FD protocols (UCOP).The operation image of UCOP is introduced below.

The programming control software (WCP) is transferred from the tool to the on-chip RAM of the MCU via the boot loader (IBL), and the transferred control software is activated for reprogramming.The software update is completed by resetting the MCU after the reprogramming operation is completed.

※For the user operation mode, refer to "How to write the flash microcontroller" on the "Flash microcontroller programmer" top page.

NETIMPRESS avant/acorde Common Product Specifications

High-Speed Programming and File Download Performance

To realize high-speed programming, the target communication baud rate, PC communication baud rate, and internal processing are accelerated.

The maximum communication baud rate with the target is 40Mbps, and the communication with the PC is connected by Gigabit Ethernet, and 8Mbyte binary files can be downloaded in 6 seconds.

Comparing Time Required for Programming

| Device | Size | Programming I/F | Command | AF430 Traditional model |

AFX100/AFX210 New model |

|---|---|---|---|---|---|

| Device A | 4Mbyte | Serial | EPR | 48 seconds | 34 seconds |

| Device B | 16Mbyte | JTAG | EPR | 94 seconds | 74 seconds |

EPR:a series of actions of erase, program, and read-verify

Communication Speed Between PC and Programmer

| Operation | File size | AF430/HSM Traditional model |

AFX100 New model |

|---|---|---|---|

| Object download(binary data) | 8Mbyte | 46 seconds | 6 seconds |

| Object download(S record data) | 23.5Mbyte | 166 seconds | 13 seconds |

| YIM folder download | 10Mbyte | 80 seconds | 6 seconds |