Multi-channel Flash Programmer

for Production Line

NETIMPRESS acorde

On-board programmer that can simultaneously program multiple on-chip flash MCUs mounted

on multi-piece PCB(PCB panel)assemblies in manufacturing lines

Overview (Programmers expected to meet diversifying demands and manufacturing a wider variety of products)

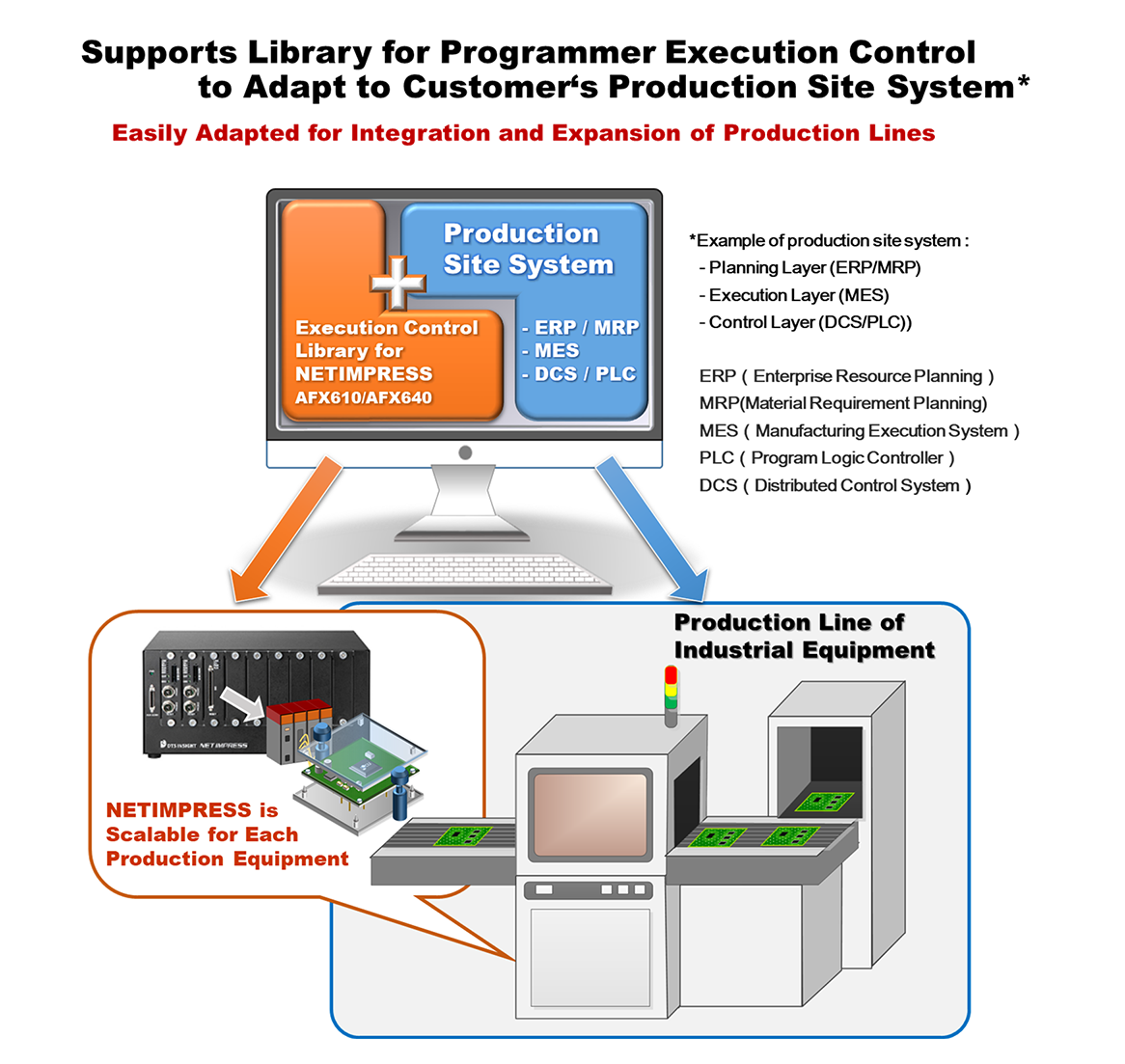

Until now, the manufacturing sites of "Embedded Systems" have aimed to improve QCD (quality, cost, delivery) by mass-producing small-quantity varieties with high quality and low cost and putting them on the market as soon as possible.In the current age of maturity, customer needs are diversifying, and the "Manufacturing" demanded by the market is changing to small-volume production of multi-product products.The problem to be solved in the changing production site is to improve the QCD in the manufacturing of diversified and multi-variety products.

Embedded system manufacturing lines adopt a production method for improving productivity and reducing costs in mass production of a small number of products and small-lot production of many products.

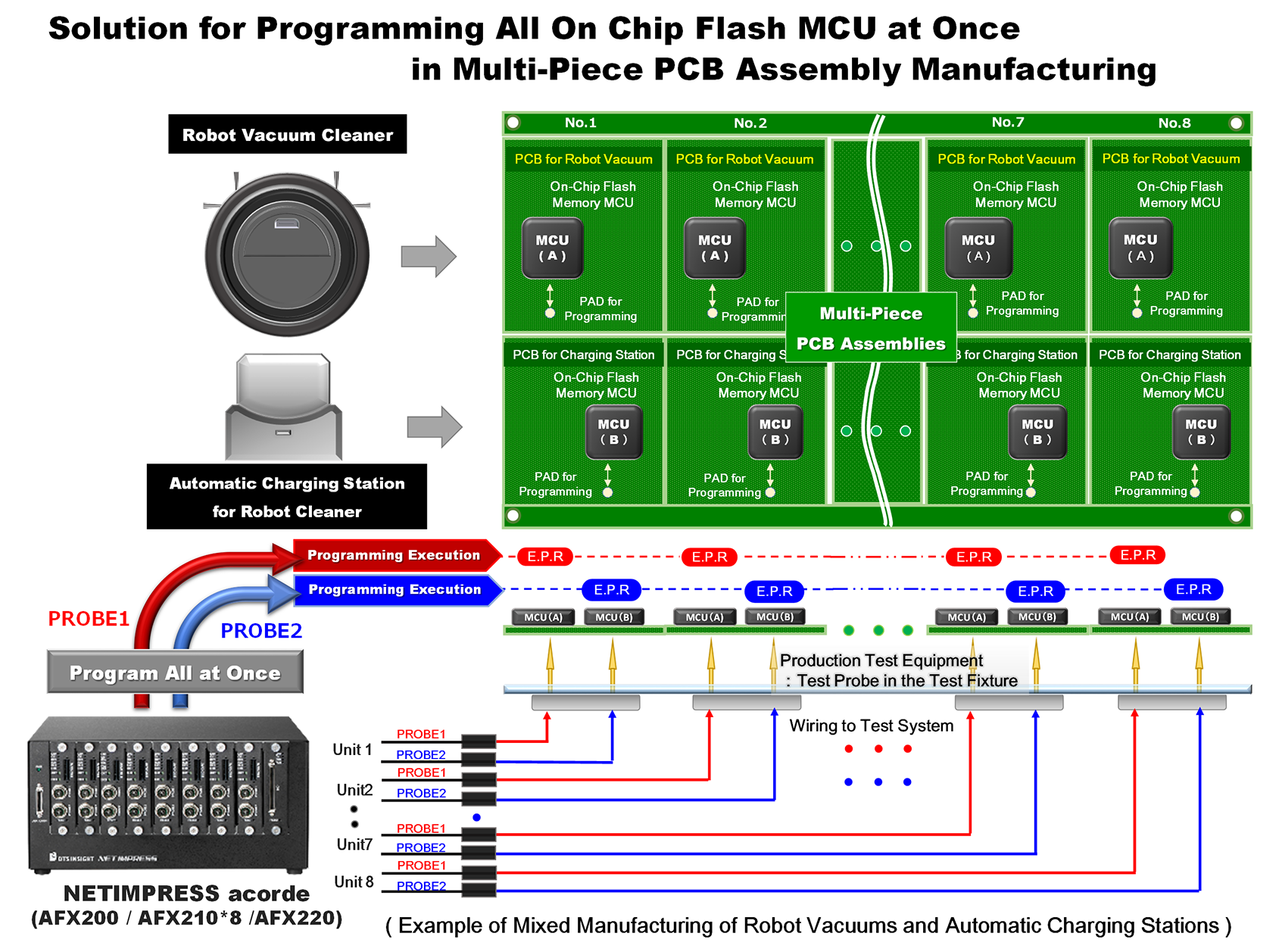

It is popular to manufacture multi-piece PCB assemblies, such as "single type multiple PCB mounting" and "mixed type PCB mounting" on one PCB. (PCB: Printed circuit board)

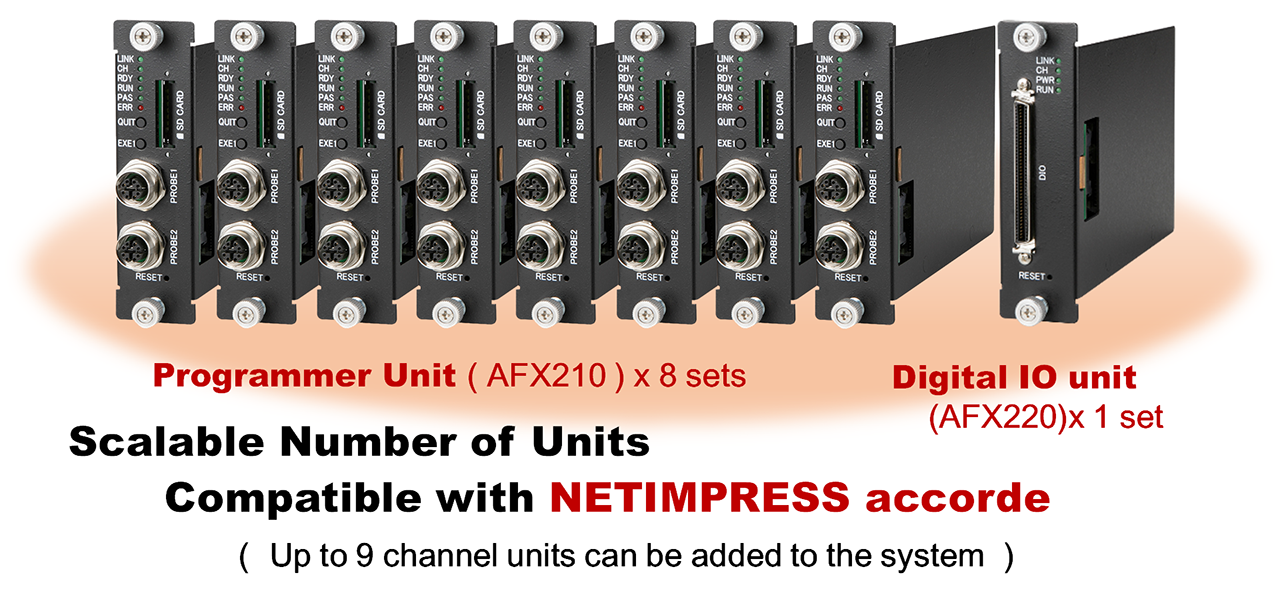

The NETIMPRESS acorde is a multi-flash programmer that can flexibly handle manufacturing from high-mix low-volume production to low-mix high-volume production.The product configuration is a programmer system equipped with communication and power supply to the base unit (AFX200) and capable of adding up to 9 units of programmer unit (AFX210) and Digital I/O unit (AFX220).

In the production of multiple on-chip flash MCUs mounted on a multi-piece PCB assembly, it is possible to perform batch programming of the same object file, or batch programming of different MCU types with different object files.

A maintenance unit (AFX230) is available as an offline setting tool for speeding up the setup change when the production lot is changed and the start-up confirmation of the production line.

【Key Features】

- As a programmer unit, the programmer product functions (avant products) are integrated into one unit card.

- Equipped with an independent execution environment for each programmer unit (saved in SD card):

Program execution can be performed by a single unit or by linking with other units - Fast environment switching for the next production lot in just 1 second

Change to the programming environment of the next lot by switching folders in SD card - Capable of expanding up to 9 units according to the field needs of the production line

- Significantly faster communication speed (compared to previous models)

(Reduces transmission time between host PC and equipment to less than 1/10 and programming time by 30%) - Enhanced affinity of production equipment

A Digital I/O unit is available for cooperation with production line equipment and PCB inspection fixtures - A unit for equipment maintenance is prepared as a separate product

For periodic inspection and maintenance of equipment for adjustment of expansion, special installation, and temporary installation of on-site equipment

Enhanced unit expansion : Supports programming up to 18 MCUs

The unit configuration mounted on the base unit is a system that can be flexibly changed according to the requirements of the manufacturing site of the production line.Up to 9 units can be mounted.

The programmer unit has been upgraded to a unit specification equipped with a 2ch probe cable connection.Up to 18 Flash MCUs can be programmed.(However, the programming operation of the programmer unit is a switching operation for each 1CH probe)Digital I/O unit can monitor and control 32 channels of digital input signals and 32 channels of digital output signals with a single unit.It is a comfortable facility for manufacturing with a high production load, such as PCB assembly with multiple on chip flash MCUs.

How to Make Effective Use of the Programmer Unit (AFX210)

In a production-line programmer application, there are many cases in which two on chip flash MCUs are programmed, which are the main MCU and sub-MCU.Since the conventional product could connect only one channel of the probe cable, it was necessary to prepare two programmer units to support two MCUs.

Also, switching the probe cable connected to the target MCU required adding an electromagnetic relay circuit to prevent electrical interference between the two programmers.

The programmer unit (AFX210) has made it possible to connect two channels of probe cables in one unit in order to eliminate the problems of productivity and manufacturing costs.An SD card is mounted for each programmer unit (AFX210), and the MCU programming environment for each probe can be saved independently.

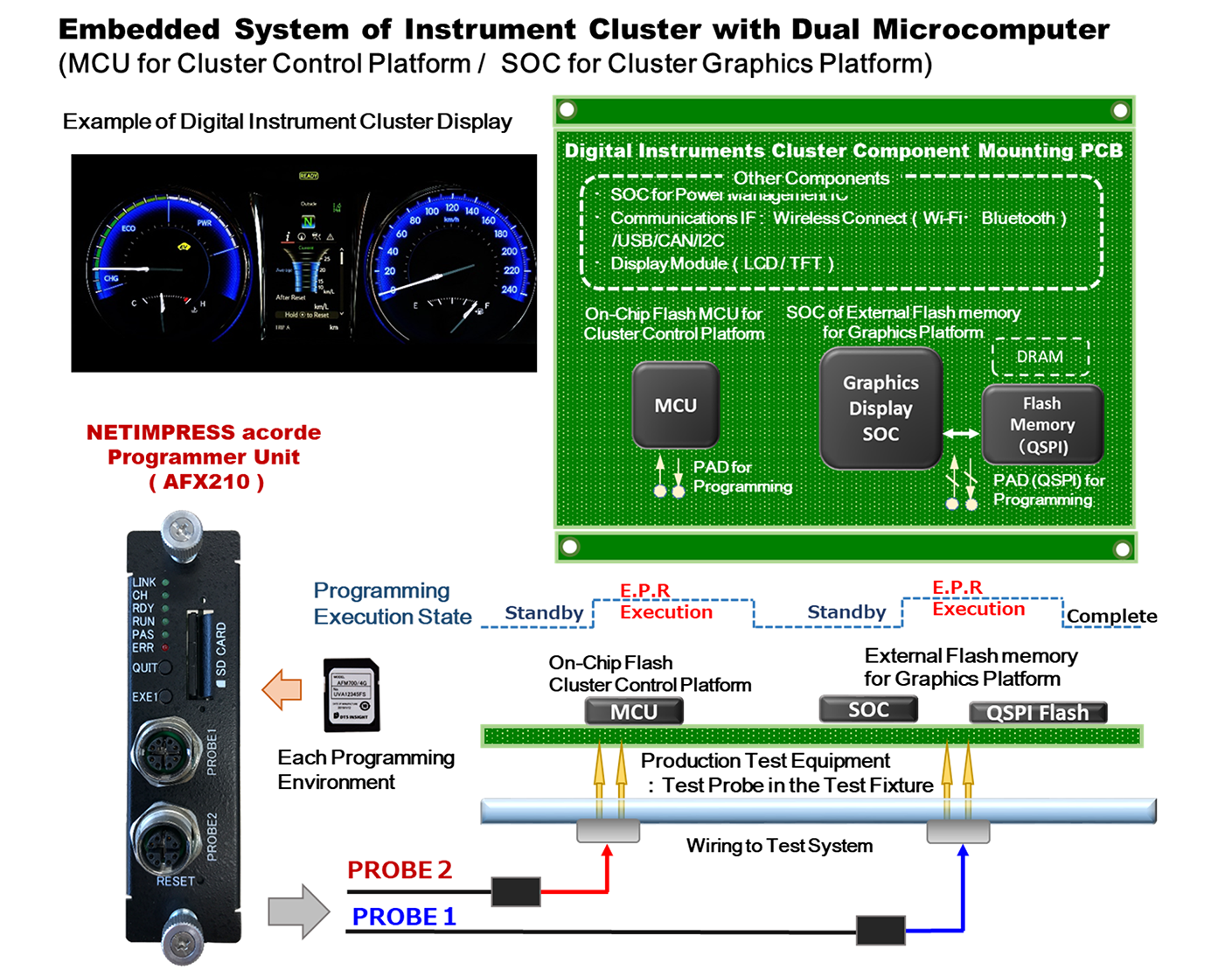

Even if the type of MCU is different, the AFX210 can program each MCU with a single unit, thus expanding the use of programming at the manufacturing site.

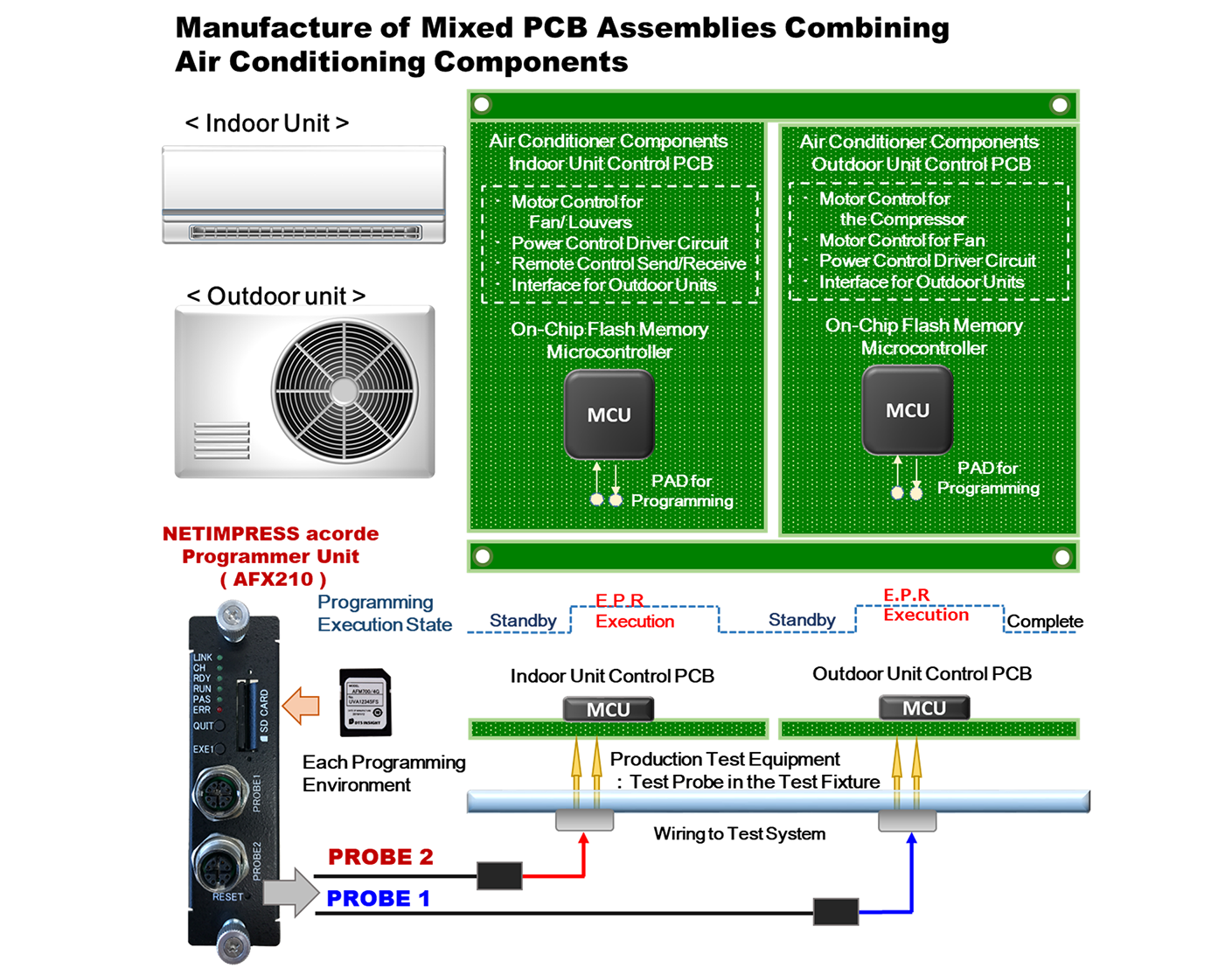

In order to make effective use of the programmer unit (AFX210), the following is an example of a use case in which two MCUs are mounted on a PCB.

Batch Simultaneous Programming Reduces Cycle Time, Improves Tact Time and Productivity

Multi-piece PCB assembly (PCB panel), in which multiple electronic circuit arrays are laid out on a PCB of a manufacturable work size, is standard on the assembly line of electronic component products for mass production.In the automation of production lines, PCB panel assembly is an effective means of improving QCD, such as reducing manufacturing costs and improving productivity.In the programming of on-chip flash MCU mounted on multi-piece PCB (PCB panel) in the production line, batch simultaneous programming of NETIMPRESS accorde shortens the operation time and greatly contributes to the improvement of tact time according to production.

As an example of programming for multi-piece PCB (PCB panel) assembly manufacturing with 16 on-chip flash MCUs, the following is an image diagram of the NETIMPRESS accorde system configuration and batch simultaneous programming production line.

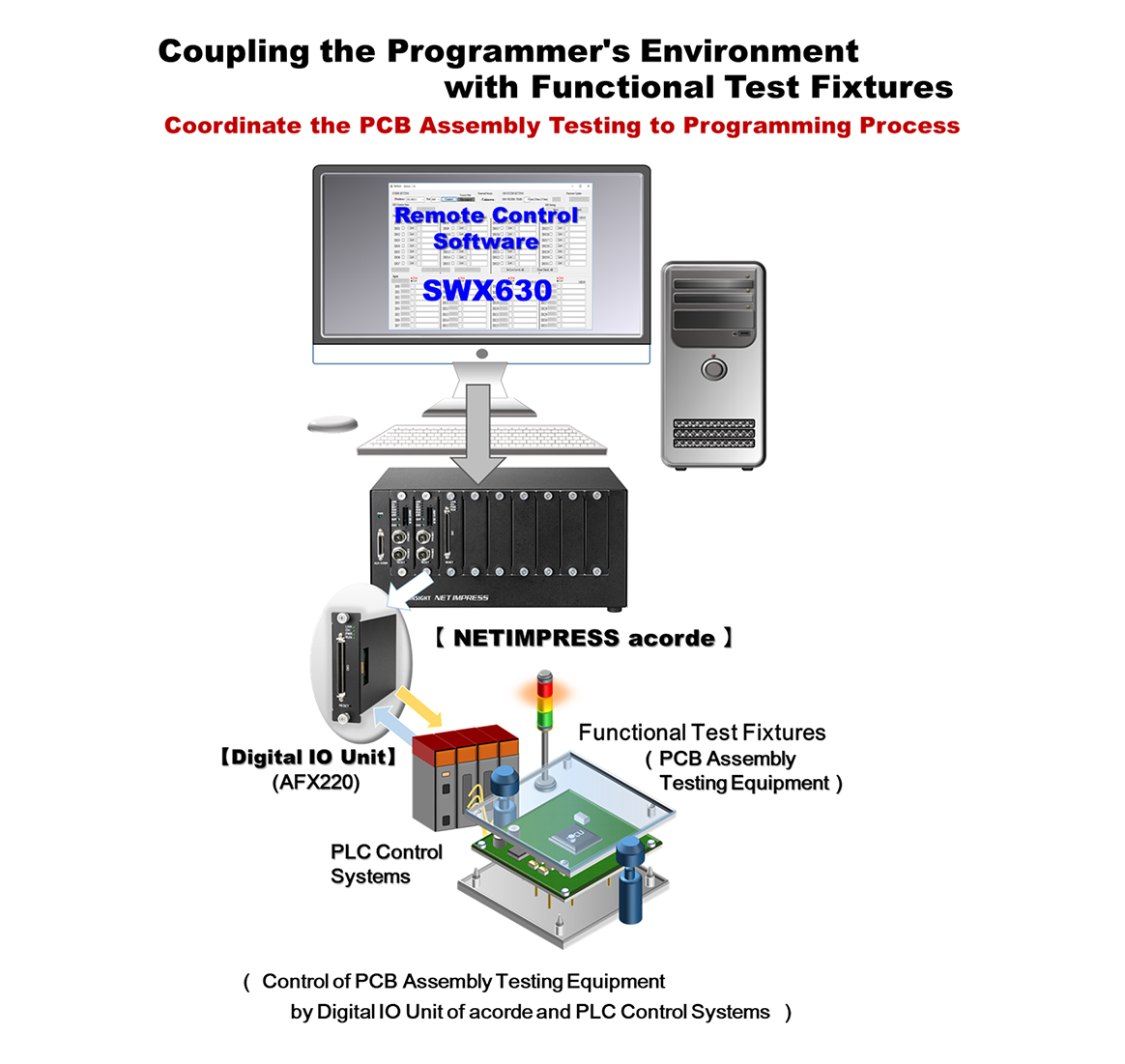

How to link the programming manufacturing process with the customer's manufacturing equipment

Over the years, the NETIMPRESS series has built up a track record of linking with many production equipment, such as PCB assembly inspection fixtures and ICT (In-circuit Testers).

NETIMPRESS acorde has added a new Digital I/O unit (AFX220) product to its lineup for interlocking with manufacturing equipment on the production line.Digital I/O unit (AFX220) is a unit for the input/output interface of 32 digital signal inputs and 32 digital signal outputs.This is a unit product for input monitoring and control of equipment for coordination of other equipment.

To incorporate "Flash Programming Execution Procedure" into the manufacturing sequence of customer manufacturing facility application, customer can easily control it by using Digital I/O unit and the dedicated remote control software (SWX630/SWX640).

Digital I/O control software (SWX630) sample software is also available for starting up new manufacturing equipment, on-site adjustment of test fixtures, and checking signal output operations on a trial basis.After checking the on-site adjustments and linkage operation, use the DLL (SWX640) of Digital I/O control package to develop the customer's manufacturing application (manufacturing execution system, equipment control, production management system) implementation.

Product Specifications of NETIMPRESS acorde Series

NETIMPRESS acorde series-product specifi cations are introduced below.

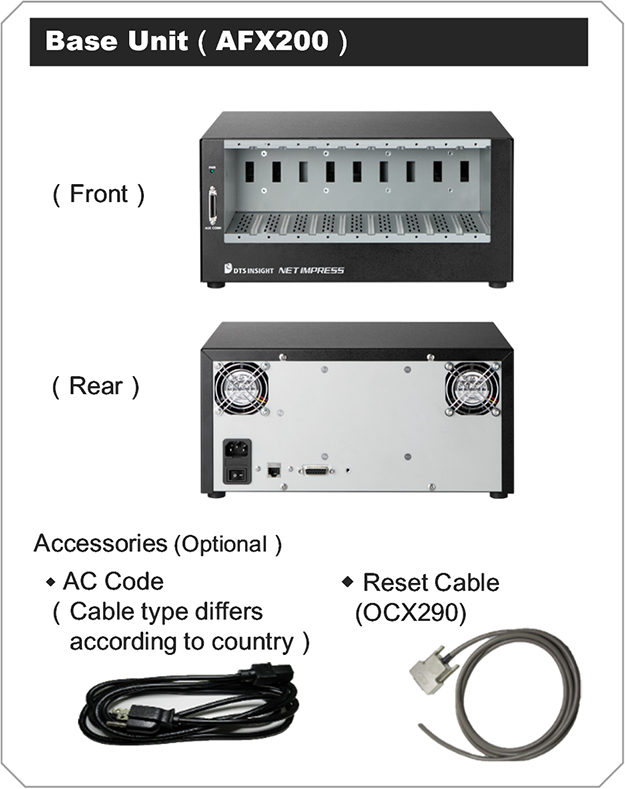

●Base Unit(AFX200)

The base unit of the "NETIMPRESS accorde" is equipped with a backplane that expands the unit, a power supply & communication function, and a cooling fan.

【Display LED・Operation SW and connector】

<Front panel> ・Display LED:Power LED

・Maintenance unit(AFX230)connector

・Unit mounting slot(There are slots, SLOT1 to 9.)

<Rear Panel> ・Operation SW:POWER SW

・AC power cord connector・Ethernet connector

・RESET connector(For programmer unit)

【Basic Specifications】

・HOST interface:ETHERNET

(10BASE-T/100BASE-TX/1000BASE-T)

Built-in 9-PORT HUB

・Storage environment -5 to 50℃ ・Operating temperature 5 to 40℃

・External dimensions 340(W)×250(D)×159(H)mm

・Weight 7.6kg

・Power Supply AC100-240V 50-60Hz (2.8A MAX)

【Accessories (Optional)】

・AC code(Cable type differs according to country)

・Reset cable (OCX290)

●Programmer Unit(AFX210)

The programmer unit performs high-speed programming for "on-chip flash MCU" or "flash memory connected to the MPU's external bus".The target-connection probe cable can be connected 2 channels.It has a slot for an SD card that saves the program environment and conditions (definition license registration).

【Display LED・Key SW・Connector】

・Probe cable connector 2CH

(Round connector M12 Female 8pin)

Adaptive probe:PHX400/PHX410

・Operation Key:QUIT・EXT・RESET Key

(Implemented embedded key SW in the panel)

・Display LED:LINK/CH/RDY/RUN/PAS/ERR

【Basic Specifications】

・Storage environment -5 to 50℃ ・Operating temperature 5 to 40℃

・External dimensions 31(W)×165(D)×113(H)mm

・Weight 300g

【Accessories (Optional)】

・Dedicated SD card (AFM700/4G or /32G)

・Probe cable(PHX400/PHX410)

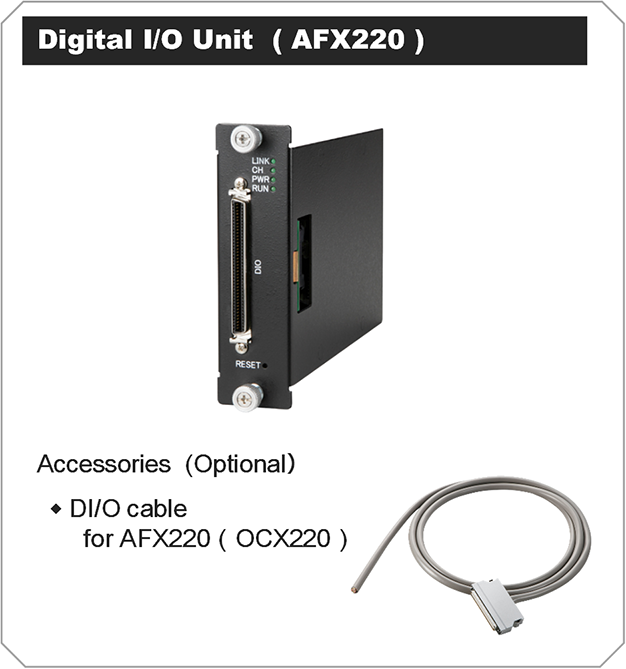

●Digital I/O Unit(AFX220)

The digital I/O unit is a unit that controls 32 ports of digital input/output for the purpose of linking with manufacturing equipment and devices.

【Display LED・Key SW・Connector】

・DI/O cable connector 1ch

(DX20-80S(HIROSE ELECTRIC CO., LTD.))

Cable to be connected:OCX220

・Operation Key:RESET(Panel embedded key SW)

・Display LED:LINK/CH/PWR/RUN

【Basic Specifications】

・Storage environment -5 to 50℃ ・Operating temperature 5 to 40℃

・External dimensions 31(W)×165(D)×113(H)mm

・Weight 300g

【Accessories (Optional)】

・DI/O cable for AFX220(OCX220)

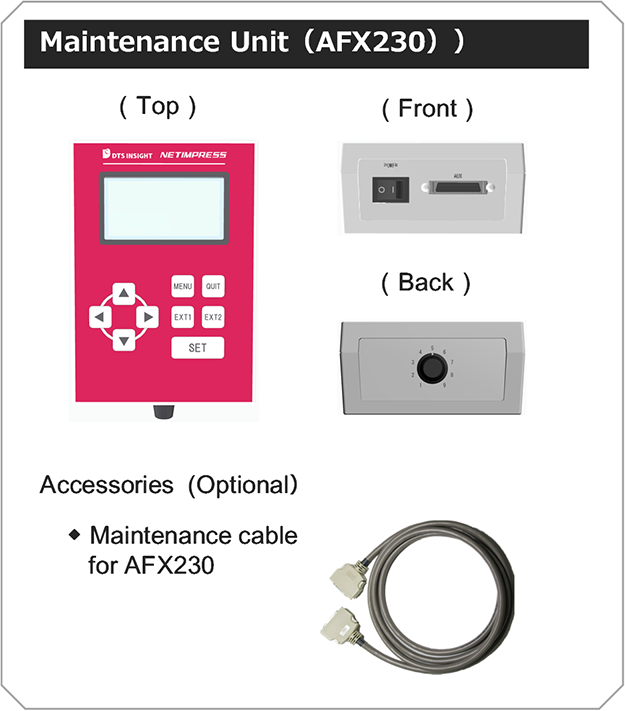

●Maintenance Unit(AFX230)

The maintenance unit (AFX230) is used for standalone operation of the programmer unit and Digital I/O unit offline.

Units for stand-alone operation can be selected using the rotary switch on the bottom.

NETIMPRESS avant/acorde Common Accessory Product Specifications

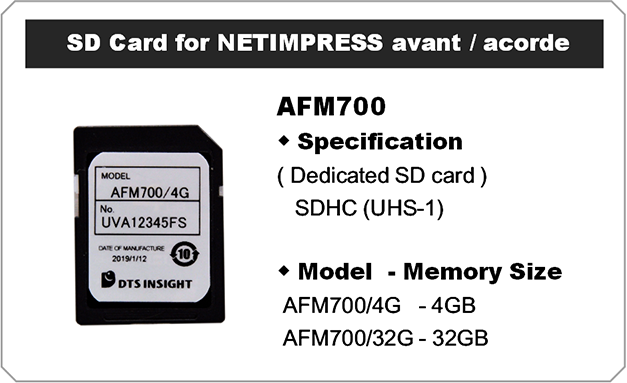

●Dedicated SD card(AFM700)

Dedicated SD card for AFX100 and AFX210 products.

It supports up to 32GB of memory size (UHS-1 standard) for high-speed data access.

Programming environment data is saved in the YIM folder in the same way as conventional products.With programming, the YIM folder can be instantly switched to the next target microcontroller.

●Definition license

NETIMPRESS avant/acorde is a general-purpose flash programmer.Each company's flash programming protocol is licensed with definitions (communication firmware) and probe logic (logic firmware corresponding to the physical interface).It is possible to expand compatible devices by adding a license to the SD card.

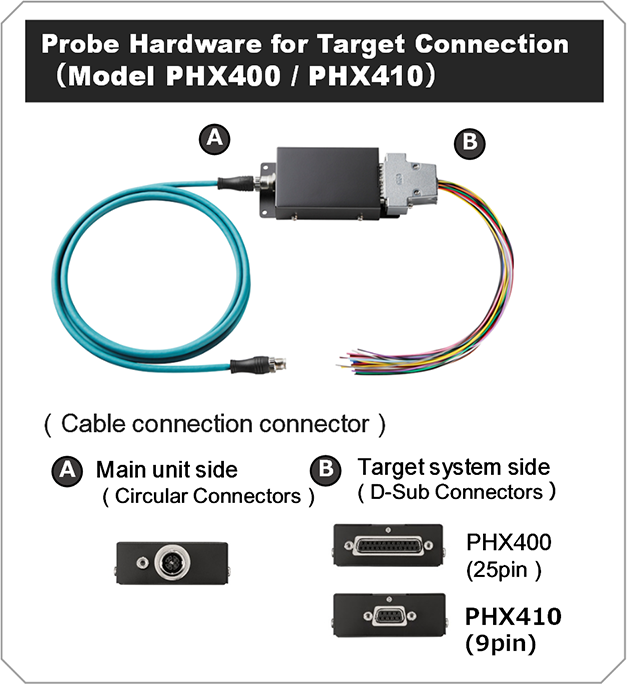

●Probe cable(PHX400/PHX410)

PHX400 is a multi-interface probe cable for various interfaces.

By default, you can extend the supported interfaces by providing serial and SPI standard support and adding probe logic licenses.

PHX410 is a probe cable for CAN/CANFD. It can be used to rewrite some of the data used in the final process (EOL:End-of-Line) of ECUproduction lines such as automotive.

【Basic Specifications】

・Cable length:

Programmer side 2m/Target Side 30cm

・Connector

Programmer side Round connector 8pin

Target Side D-SUB connector

(PHX400:25pin・PHX410:9pin)

・External dimensions 65(W)×95(D)×25(H)mm

【Probe Logic License】

Probe logic (firmware corresponding to the physical interface) is licensed.

It is possible to support the probe interface by installing the license on the purchased probe.

・PLX410 : Serial probe logic license(Standard installation on PHX400)

・PLX420 : JTAG probe logic license(Paid license) For PHX400

・PLX430 : SWD probe logic license (Paid license) For PHX400

・PLX440 : QSPI probe logic license (Paid license) For PHX400

・PLX460:BDM probe logic license (Paid license) For PHX400 用

・PLX450 : CAN/CANFD probe logic license (Standard installation on PHX410)

NETIMPRESS avant/acorde Common Product Specifications

High-Speed Programming and File Download Performance

To realize high-speed programming, the target communication baud rate, PC communication baud rate, and internal processing are accelerated.

The communication baud rate with the target is max. 40Mbps, communication with the PC is connected by Gigabit Ethernet, and 8Mbyte binary files can be downloaded in 6 seconds.

Comparing Time Required for Programming

| Device | Size | Programming I/F | Command | AF430 Traditional model |

AFX100/AFX210 New model |

|---|---|---|---|---|---|

| Device A | 4Mbyte | Serial | EPR | 48 seconds | 34 seconds |

| Device B | 16Mbyte | JTAG | EPR | 94 seconds | 74 seconds |

EPR:a series of actions of erase, program, and read-verify

Communication Speed Between PC and Programmer

| Operation | File size | AF430/HSM Traditional model |

AFX100 New model |

|---|---|---|---|

| Object download(binary data) | 8Mbyte | 46 seconds | 6 seconds |

| Object download(S record data) | 23.5Mbyte | 166 seconds | 13 seconds |

| YIM folder download | 10Mbyte | 80 seconds | 6 seconds |